Racking Inspections – Protect Your Warehouse, Comply with Safety Regulations

Why Racking Inspections Are Crucial for Your Business

Warehouse racking systems are the backbone of effective storage and logistics operations, yet they pose significant safety risks if not properly maintained. The vast weight of goods stored at height means that any racking collapse can have devastating consequences — from serious injury or death to costly damage and extended business downtime. Forklifts, essential for moving heavy loads, introduce further risk as impacts can weaken or damage racking components, often unnoticed or unreported due to operator concerns. Regular, thorough racking inspections are essential to minimise these hazards, protect your workforce, and keep operations running smoothly.

Ignoring potential racking damage or maintenance needs can lead to catastrophic outcomes, including injury to employees, legal penalties, loss of stock, expensive downtime, and reputational damage. To safeguard your business, a robust inspection regime with clear documentation is not just best practice — it’s a critical legal and moral responsibility.

Comprehensive Racking Inspection Products from HSE Store

At HSE Store, we provide an extensive range of racking inspection products from Good to Go Safety that make your inspection process straightforward, efficient, and compliant with all relevant UK legislation:

-

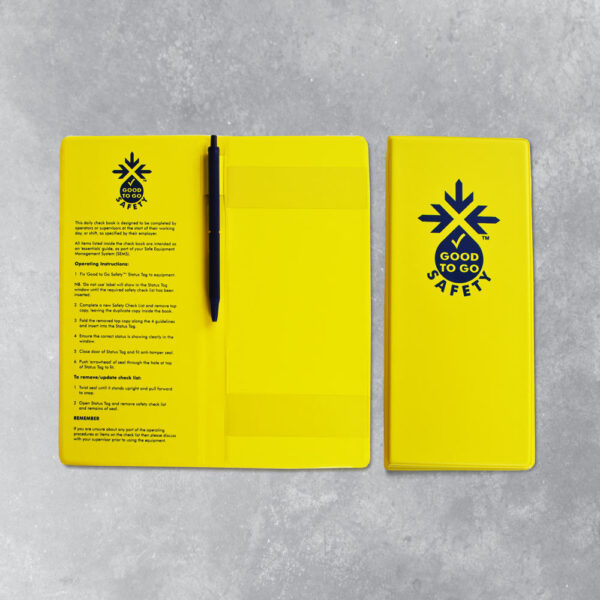

Racking Inspection Checklists/Check Books: Designed specifically for warehouse racking systems, our checklists guide users through essential visual checks covering structural integrity, load conditions, cleanliness, and safety hazards. Each checkbook contains 25 checklists, with carbonless duplicates retained for audit trails.

-

Status Tags: Attach these clearly visible tags to each racking bay or aisle alongside Safe Working Load (SWL) signs. Tags display the date and outcome of the last inspection and provide “Do Not Use” status when damage or issues are found, ensuring immediate visibility of racking safety status.

-

Tamper Evident Seals: Prevent unauthorised removal or alteration of inspection checklists and tags, maintaining integrity and accountability.

-

Information Posters: Promote awareness and remind staff of inspection protocols and the importance of routine visual checks.

-

Protective Wallets & Storage Boxes: Protect inspection books, tags, and accessories ensuring all records are clean, safe and accessible to site management and inspectors.

These products encourage daily or routine inspections, empowering warehouse teams to quickly identify issues before they escalate, helping you maintain compliance with PUWER, WAHR, HSE, and SEMA regulations.

Benefits of a Proactive Racking Inspection Regime

Implementing a structured inspection and maintenance protocol for your warehouse racking delivers substantial benefits:

-

Prevents Dangerous Failures: Early detection of cracks, dents, corrosion or load imbalances reduces risk of catastrophic collapse.

-

Protects Workforce Safety: Safeguards operators, warehouse staff and visitors from injury or fatal accidents caused by racking failure.

-

Ensures Compliance & Avoids Fines: Demonstrates adherence to legal obligations and best practices, reducing risk of prosecution or penalties.

-

Maintains Business Continuity: Minimises costly downtime, damage claims, and stock loss linked to racking failures or warehouse incidents.

-

Strengthens Risk Management: With clear documentation and visual status tags, you can easily manage inspection results, track defects and coordinate prompt repairs.

Suitable Industries and Key Users of Racking Inspection Products

Racking inspections are indispensable across any sector relying on pallet racking or warehouse storage systems:

-

Warehousing and Logistics

-

Retail Distribution Centres

-

Manufacturing and Industrial Storage

-

Food and Beverage Operations

-

Pharmaceuticals and Healthcare Storage

Key personnel who routinely use or benefit from racking inspection products include:

-

Warehouse Operators & Forklift Drivers: Perform daily visual checks and report potential damage or hazards.

-

Warehouse Supervisors & Managers: Oversee regular inspection schedules and ensure damaged racking is quarantined.

-

Health & Safety Officers: Audit inspection records, investigate incidents, and enforce compliance.

-

Maintenance Teams: Use inspection data to coordinate prompt repairs and track recurring faults.

-

Business Owners & Directors: Responsible for legal compliance, operational safety, and protecting the company’s reputation.

How Good to Go Safety’s Racking Inspection System Works

Our system simplifies racking safety management by coupling straightforward inspection checklists with clear, visual status indicators:

-

Conduct a routine visual inspection of each racking bay using the checklist, covering structural integrity, safe loading, housekeeping, and protection devices.

-

Once complete, remove the top copy of the checklist and insert it inside the status tag fixed to the racking bay, clearly showing the inspection date and status.

-

Display a “Do Not Use” message if any faults are identified, effectively quarantining the bay until repairs are completed.

-

The duplicate checklist remains in the book as proof of inspection for management and regulators.

-

Repeat the process daily, weekly, or as warranted by risk assessment or operational intensity—adapting easily to your business needs.

This consistent method removes uncertainty, enforces compliance, and keeps warehouse racking safe “Good to Go”.

Frequently Asked Questions (FAQs)

1. How often should warehouse racking be inspected?

Racking should be visually inspected daily or before each shift, with a thorough examination at least annually, or immediately after any reported damage or impact.

2. Who should conduct racking inspections?

Visual checks can be done by trained warehouse staff or forklift operators, while thorough inspections and assessments are carried out by competent persons, such as SEMA-approved inspectors.

3. What should be done if damaged racking is found during inspection?

The damaged section must be clearly tagged “Do Not Use” and access restricted immediately. Repairs should be undertaken promptly, and the racking re-inspected before returning to safe use.

4. What records are required for compliance?

Records of all inspections, defects, and repairs must be retained. The Good to Go Safety checklists provide duplicate copies, creating a comprehensive audit trail to demonstrate compliance.

5. Why invest in dedicated racking inspection products instead of generic checklists?

Purpose-built checklists address all critical safety points specific to racking systems and integrate with visual status tags. This approach improves communication, compliance, and helps prevent tragic collapses.

Choose HSE Store for trusted, industry-leading Racking Inspection products — protect your warehouse, employees, and reputation with comprehensive safety and compliance solutions.