In the high-stakes environment of UK logistics, pallet racking is the backbone of the supply chain. It is designed to withstand immense pressure, yet its structural integrity is surprisingly fragile when faced with the daily rigours of forklift operations. A single 5-tonne forklift moving at walking pace carries enough kinetic energy to buckle a steel upright instantly, potentially triggering a progressive collapse.

Ensuring racking safety is not merely about avoiding accidents; it is about legal compliance, operational efficiency, and protecting your most valuable asset: your people. This comprehensive guide provides a deep dive into the regulatory landscape, the physics of racking protection, and the visual management systems that turn a “standard” warehouse into a gold-standard facility.

The Legal Framework: PUWER, HSG76, and Your Duty of Care

In the UK, the safety of storage equipment is governed by several layers of legislation. Primarily, racking falls under the Provision and Use of Work Equipment Regulations 1998 (PUWER). Under PUWER, an employer has a non-negotiable legal duty to ensure that work equipment is:

Suitable for the intended use: This includes ensuring the racking brand and type are appropriate for the environment (e.g., galvanized steel for cold storage).

Maintained in a safe condition: Regular maintenance is a proactive requirement, not a reactive one.

Inspected by competent persons: Inspections must be formalised and documented.

Supplementing this is the HSE’s specific guidance document, HSG76 (Warehousing and Storage: A Guide to Health and Safety). This document outlines that racking should be considered “specialist equipment.” If an accident occurs and it is found that you haven’t followed the guidance in HSG76, the HSE will use this as evidence of a breach of the Health and Safety at Work Act.

Implementing the "Good To Go" Inspection Regime

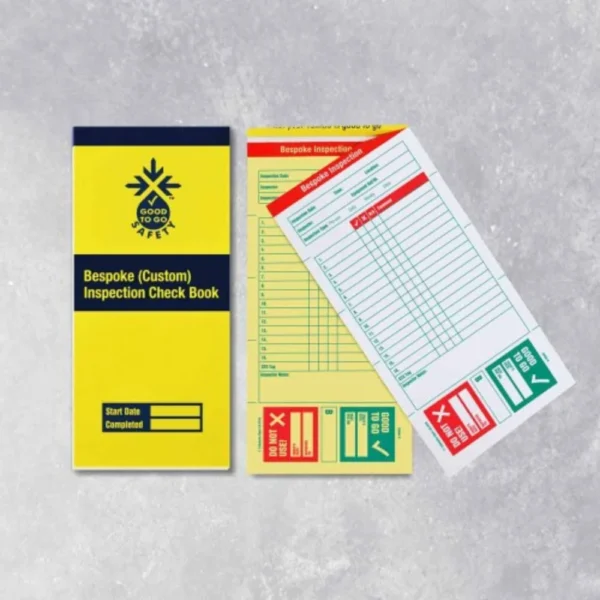

One of the biggest challenges for Warehouse Managers is bridging the gap between “knowing” a rack should be inspected and “proving” it has been done. This is where the Good To Go Safety Racking Inspection System becomes invaluable.

Rather than relying on loose sheets of paper or a manager’s memory, a systematic “Tag and Book” approach ensures accountability:

Visual Deterrent & Reminder: By attaching a “Good To Go” tag to the end of a racking run, you provide a clear visual indicator. If a tag is empty or shows a “Fault” sign, staff know instantly not to use that bay.

Structured Checklists: Your team uses dedicated racking inspection books that list specific components—uprights, beams, floor fixings, and locking pins.

The Paper Trail: Once a check is completed, a carbon copy remains in the book as a permanent record, while the top copy is placed in the tag. This creates a “Safety Audit Trail” vital for insurance purposes and HSE inspections.

-

Equipment Inspections – Daily Checklist Kits

£107.40 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Equipment Inspections – Weekly Checklist Kits

£34.39 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Equipment Inspection Pre-Use Check Book – 25 Checklists

£6.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

Physical Defence: Integrating Racking Protection

While inspections identify problems, Racking Protection prevents them. High-quality physical barriers are your insurance policy against structural failure. At HSE Store, we supply a range of defences designed to absorb and deflect impact:

Steel Upright Protectors: These heavy-duty shields are bolted to the floor in front of the racking uprights. They are the first line of defence, ensuring a stray forklift fork hits steel rather than the racking itself.

Polymer / Plastic Upright Guards: These “clip-on” protectors are ideal for high-traffic areas. They deform on impact, absorbing energy and springing back into shape, protecting both the rack and the forklift.

Rack End Barriers: The most dangerous area is the end of an aisle, where forklifts turn corners. Our heavy-duty rack end barriers create a physical wall, preventing “corner-cutting” accidents that could take down an entire row.

Corner Guards & Bollards: For doorways and pedestrian walkways, steel bollards provide a visible “stop” for vehicles, ensuring they maintain a safe distance.

-

Loadtek Racking Protection Barrier – U Shape Kit

From £188.61 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

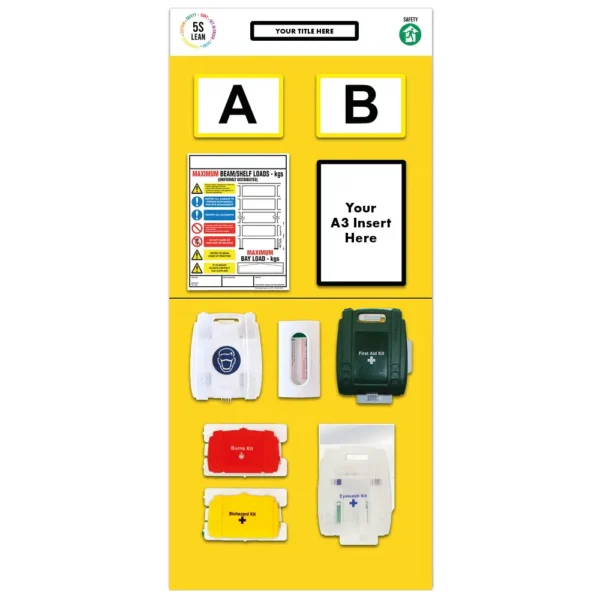

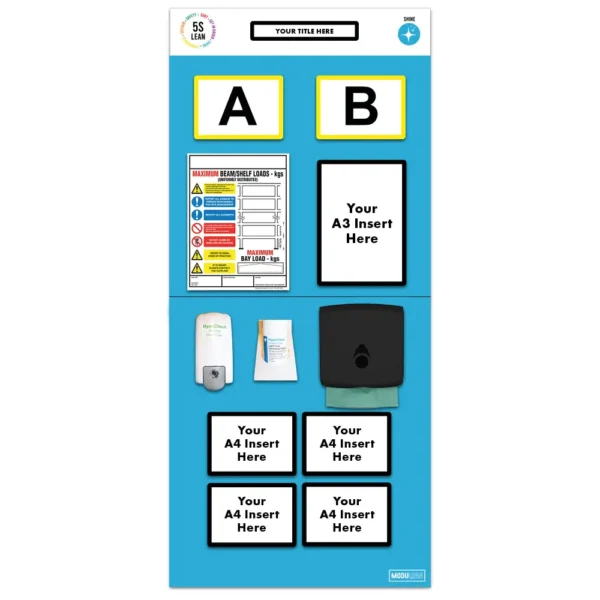

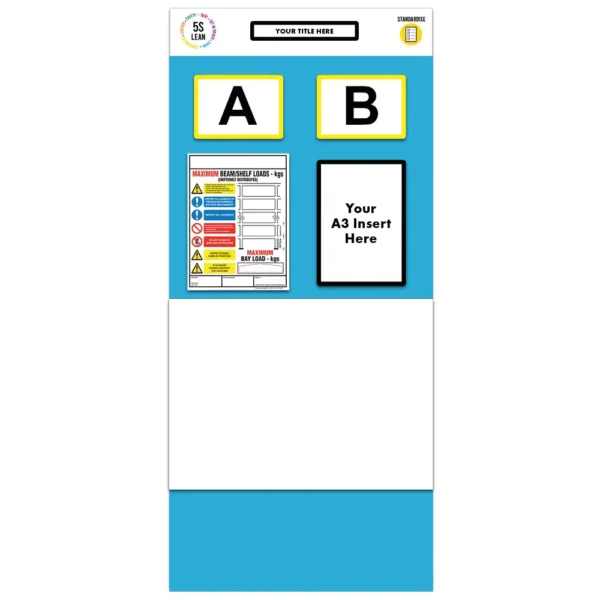

Visual Management: Modulean® Rack End Boards

Often, the ends of racking aisles are “dead space.” However, this is the most high-visibility area of your warehouse. Our Modulean® Rack End Boards transform these spaces into centralised safety hubs.

These 2000mm high boards integrate 5S Lean principles into your racking safety strategy:

Cleaning Stations: Ensure that aisles remain free of debris—a major cause of forklift skids—by having brooms and dustpans exactly where they are needed.

Fire Safety & First Aid: Seconds matter during an emergency. Mounting extinguishers, fire blankets, and first aid kits on a Fire Station Rack End Board ensures equipment is accessible without cluttering floor space.

Safety Assessments: The Rack Assessment Board includes a racking self-assessment chart, making it easy for staff to cross-reference damage levels against the SEMA traffic light system.

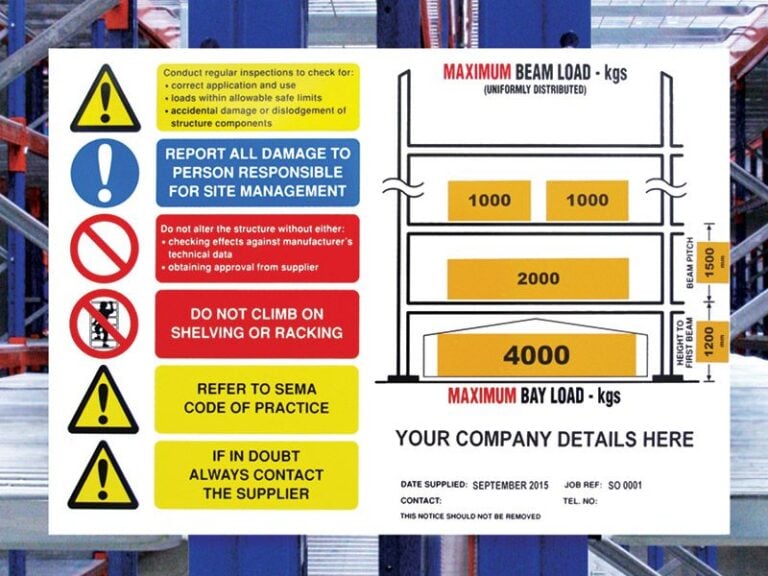

Mandatory Load Notices: Every Modulean board includes a weight load notice. These are a legal requirement for all racking, informing staff of the maximum pallet and bay weights to prevent overloading.

-

Modulean Rack End Board – First Aid

From £448.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Modulean Rack End Board – Sanitising

From £408.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Modulean Rack End Board – White Board

From £350.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

Technical Analysis: The "Red, Amber, Green" Risk Levels

When damage is found during a “Good To Go” inspection, it must be categorised using the SEMA traffic light system. This removes the guesswork:

GREEN (Low Risk): Damage is within SEMA limits. The rack is safe to use but must be recorded and monitored.

AMBER (Hazardous): Damage exceeds limits but doesn’t warrant immediate offloading. The rack should be offloaded within four weeks and must not be reloaded until repaired.

RED (Critical): Damage is serious (e.g., a visible tear or major buckle). You must offload the bay immediately, cordon it off, and cease use until it is professionally repaired.

The Science of Load Notices and Weight Limits

Racking strength is determined by the distance between horizontal beams. A common mistake is “accidental overloading”—moving a beam level to accommodate taller pallets without realising that increasing the “unsupported length” of an upright significantly reduces its total load capacity.

Your Modulean Rack End Boards provide the perfect home for these notices, which must detail:

Maximum Pallet Weight: The weight of a single pallet.

Maximum Compartment Load: Total weight allowed on a pair of beams.

Maximum Bay Load: The total weight the entire “tower” (floor to ceiling) can handle.

Human Factors: Culture and Housekeeping

You can have the best barriers, but if your warehouse culture is poor, your risk remains high.

No-Blame Culture: If an FLT driver hits a rack and fears they will be fired, they will hide the damage. Reporting damage is the most important safety act a driver can perform.

Housekeeping: Use your Cleaning Shadow Boards to maintain floor cleanliness. Dust and pallet wrap on the floor can interfere with forklift braking and steering.

Illumination: Ensure lighting levels are sufficient at the highest levels. If a driver can’t see the entry point at 10 metres high, an impact is inevitable.

Conclusion

Warehouse racking safety is a multi-layered commitment. By combining the Good To Go Safety inspection system, robust physical racking protection, and the visual clarity of Modulean Rack End Boards, you create a fortress of safety. Don’t wait for a “near miss”—equip your team with the right tools today to ensure your warehouse remains a safe, productive, and compliant environment.

FAQ's

Is a racking inspection a legal requirement?

Yes. Under PUWER 1998, racking is “work equipment” and must be inspected to ensure it remains safe for use.

How often should I use the Good To Go Safety check books?

HSE recommends weekly internal inspections. In high-intensity, 24/7 operations, many managers opt for daily checks.

What are Modulean Rack End Boards?

These are large shadow boards designed to fit at the end of racking aisles. they hold cleaning gear, fire safety equipment, and first aid kits while displaying aisle markers and load notices.

Why are weight load notices mandatory?

Without them, staff have no way of knowing if they are overloading the structure, which is the leading cause of racking fatigue and failure.

Do I really need rack end barriers?

Yes. The ends of aisles are the most common sites for major impacts. Barriers prevent forklifts from hitting the structure during tight turns.

Can I repair damaged racking myself?

No. Repairs must be done by trained professionals using “like-for-like” components to maintain the manufacturer’s warranty and structural integrity.

What is the difference between Amber and Red risk?

Red requires immediate offloading. Amber allows for 4 weeks of use, but the rack cannot be reloaded once emptied until it is fixed.

Do I need to bolt my racking to the floor?

Yes. Floor fixings are essential for stability and to prevent the rack from shifting during loading or minor impacts.

Can Modulean boards be customised?

Yes. They come in 7 designs (Cleaning, Fire, First Aid, etc.) and multiple colours to suit your warehouse colour-coding.

How long should I keep inspection records?

At least three years, though keeping them for the life of the racking is recommended for a complete audit trail.

What is a SEMA inspection?

An annual technical audit performed by a SEMA Approved Rack Inspector (SARI) to check for millimetre-level deflections.

Does second-hand racking need an inspection?

Absolutely. It must be checked for pre-existing damage and installed according to the original manufacturer’s specifications.

What is the "unsupported length" of an upright?

It is the distance between beam levels. If you increase this distance, you decrease the total weight capacity of the bay.

Are plastic upright protectors better than steel?

Steel is rigid and stops a forklift, but can damage the floor. Plastic absorbs energy and is often better for frequent, low-speed bumps.

What should I do if a safety pin is missing?

Replace it immediately. Safety pins prevent beams from being accidentally dislodged by a forklift fork when lifting a pallet.