-

Equipment Inspections – Daily Checklist Kits

£107.40 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Equipment Inspections – Weekly Checklist Kits

£34.39 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

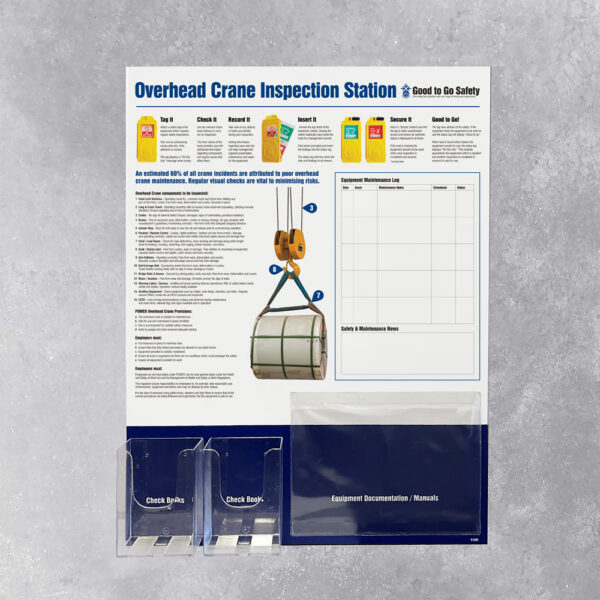

Good To Go Safety: The Ultimate Equipment Tagging & Inspection System

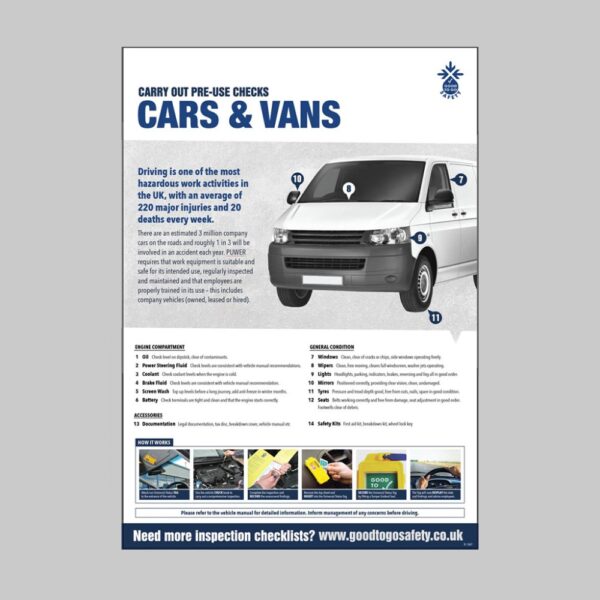

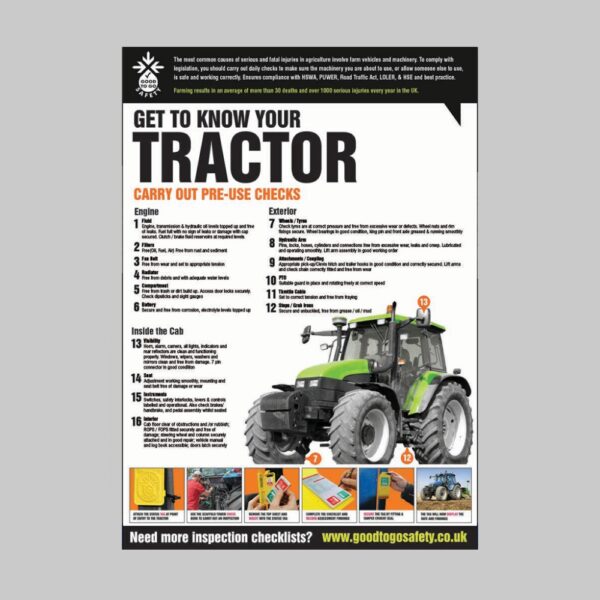

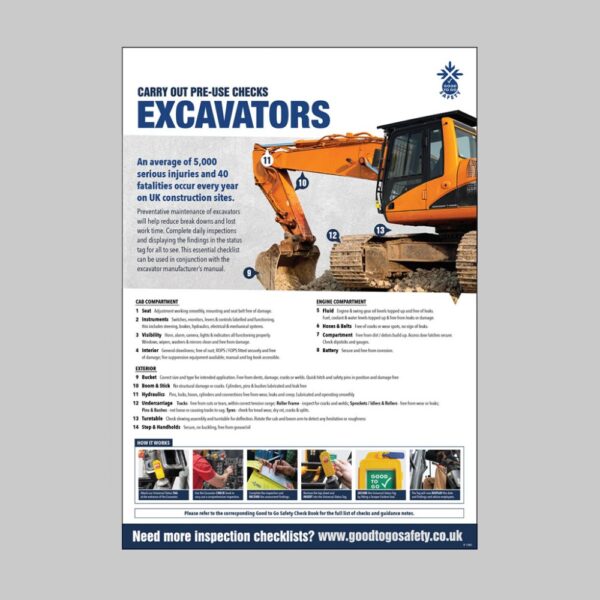

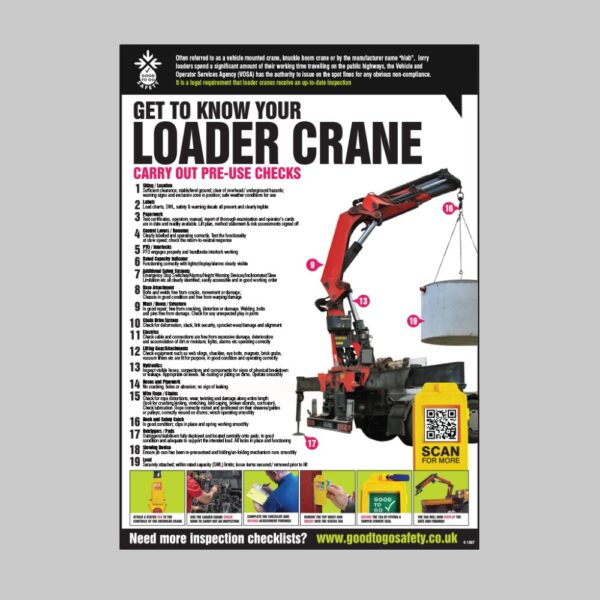

Ensure your workplace equipment is safe, compliant, and ready for operation with the Good To Go Safety range, now available at HSE Store. As a multi-award-winning safety solution, Good To Go Safety revolutionises the way businesses manage equipment maintenance and inspections. Designed to bridge the gap between assumption and verified safety, this innovative Safe Equipment Management System (SEMS) allows employers to efficiently check, tag, and record the status of almost any piece of workplace equipment. From construction sites to busy warehouses, this system is an essential tool for reducing risk and protecting your workforce.

The core of the Good To Go Safety system is its simple yet highly effective "Check, Tag, Record" process. It replaces ad-hoc or verbal checks with a visible, standardised procedure. By attaching a universally adaptable status tag to your equipment, you create an immediate visual reference point for all employees. If the equipment has not been checked or has failed an inspection, the tag clearly displays a "Do Not Use" message. Once a checklist is completed and passed, the green "Good To Go" insert is placed into the tag, instantly communicating that the equipment is safe for use. This eliminates guesswork and ensures that faulty machinery is locked out of operation immediately.

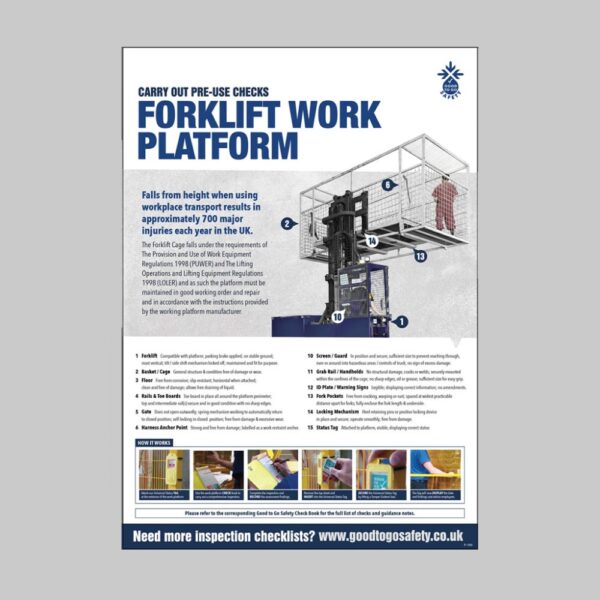

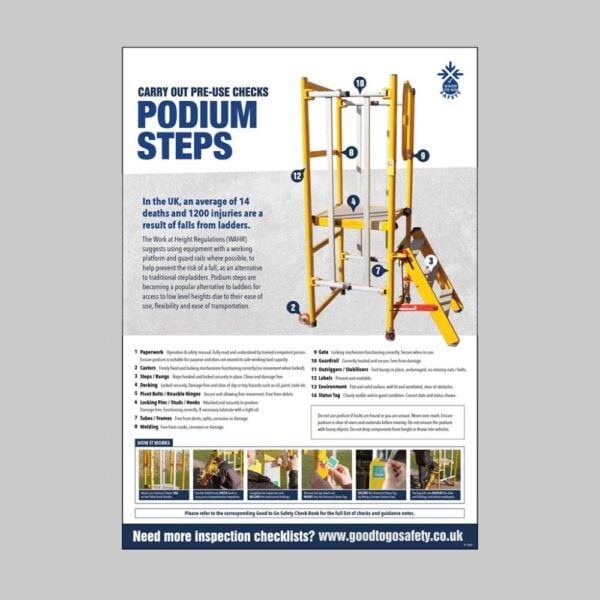

Compliance with UK health and safety legislation is a critical responsibility for any business owner or site manager. The Good To Go Safety range is specifically designed to help you meet the requirements of regulations such as PUWER (Provision and Use of Work Equipment Regulations), LOLER (Lifting Operations and Lifting Equipment Regulations), and WAHR (Work at Height Regulations). By implementing these inspection checklists, you can demonstrate a clear audit trail of preventative maintenance, proving that you have taken all "reasonably practicable" steps to ensure equipment safety in the event of an accident or HSE investigation.

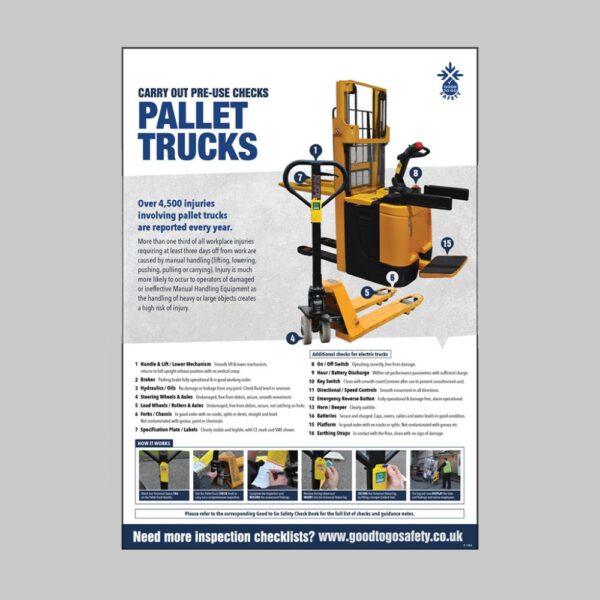

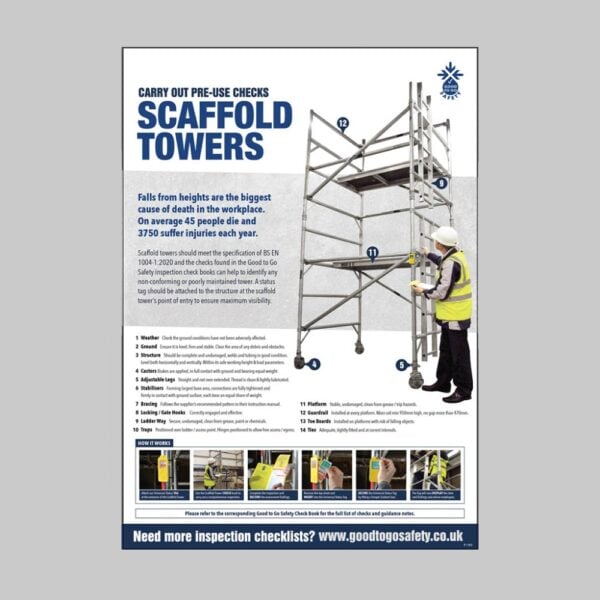

One of the standout features of this range is its incredible versatility. We stock specific inspection checklists for a vast array of industrial equipment. Whether you are managing a fleet of vehicles or a complex construction site, there is a tailored solution available. The system covers everything from heavy machinery like excavators and forklifts to working-at-height essentials like ladders, podium steps, and scaffold towers. Universal compatibility means the status tags can be fitted to almost anything, ensuring a consistent safety message across your entire facility.

Key benefits of the Good To Go Safety system include:

-

Instant Visibility: Clearly displays if equipment is "Good To Go" or "Do Not Use," reducing the risk of using faulty kit.

-

Legislative Compliance: Helps meet obligations under PUWER, LOLER, WAHR, and CDM regulations.

-

Comprehensive Audit Trail: Duplicate checklist copies provide a permanent record of all maintenance and inspections.

-

Durability: Weather-resistant, UV-stable polypropylene tags designed for harsh indoor and outdoor environments.

-

Reduced Maintenance Costs: Early detection of faults prevents minor issues from becoming expensive repairs.

-

Universal Fit: One tag design fits all equipment types, simplifying stock management.

Beyond just compliance, implementing Good To Go Safety fosters a proactive safety culture within your organisation. It empowers your employees to take ownership of their safety by providing them with the tools to perform pre-use checks confidently. The checklists are written in clear, jargon-free English and guide the user through specific checks relevant to that piece of equipment. This ensures that inspections are not just a "tick-box exercise" but a thorough review of critical safety components, from tyre pressure on telehandlers to the integrity of rungs on a ladder.

Durability is paramount for equipment that lives on building sites or in industrial yards. The Good To Go Safety status tags are manufactured from high-impact polypropylene, making them tough, flexible, and resistant to oils, chemicals, and extreme weather conditions. Unlike paper tags that can tear or fade in the rain, these robust pods protect the inspection records inside, ensuring that critical safety information remains legible and secure regardless of the environment.

At HSE Store, we offer the full Good To Go Safety ecosystem, including starter kits, refill checklists, and individual status tags. We understand that a robust inspection regime is the backbone of a safe workplace. By choosing this market-leading tagging system, you are investing in a solution that saves time, reduces paperwork, and, most importantly, saves lives. Browse the range above to find the specific inspection checklists for your equipment and start building a safer, more compliant workplace today.

Good To Go Safety – Frequently Asked Questions

1. What is the Good To Go Safety system and how does it work? Good To Go Safety is a Safe Equipment Management System (SEMS) designed to ensure workplace equipment is safe to use. It operates on a simple "Check, Tag, Record" basis. A universal Status Tag is attached to the equipment. An employee performs a pre-use inspection using a specific checklist. If the equipment passes, the signed checklist is placed inside the tag, displaying a "Good To Go" message. If it fails, the checklist is removed, displaying a "Do Not Use" prohibition symbol.

2. Which UK regulations does the Good To Go Safety range help me comply with? This system is an excellent tool for meeting your obligations under several key regulations, including the Provision and Use of Work Equipment Regulations (PUWER), the Lifting Operations and Lifting Equipment Regulations (LOLER), the Work at Height Regulations (WAHR), and CDM regulations. By providing a clear audit trail of inspections, you can demonstrate that you have taken reasonable steps to ensure safety.

3. Is the Good To Go Safety system suitable for outdoor use? Yes, absolutely. The Status Tags are manufactured from high-impact polypropylene, which is UV stable, durable, and weather-resistant. They are designed to withstand harsh industrial environments, rain, and dirt, ensuring the safety information inside remains clean and legible even on outdoor construction sites or yards.

4. Do I need to buy different tags for different types of equipment? No, you do not. One of the biggest advantages of this system is that the Status Tag is universal. The same tag fits onto a ladder, a forklift, scaffolding, or a pallet truck. You simply purchase the specific checklist pads relevant to your equipment type, and they will all fit the same standard tag.

5. What should I do if a piece of equipment fails the inspection? If a fault is identified during the pre-use check, the top copy of the checklist should not be placed in the tag. Instead, the tag will default to display the "Do Not Use" message (a red circle with a diagonal line). The faulty equipment should be quarantined, and the checklist handed to a supervisor to arrange maintenance. This ensures no one accidentally uses unsafe machinery.

6. Why do the inspection checklists come with a carbon copy? The duplicate (carbon) copy is essential for your records and audit trail. While the top copy is displayed on the equipment for visibility, the duplicate remains in the book. This allows management to monitor inspection frequency, track recurring faults, and keep a permanent history of maintenance for health and safety audits.

7. How do I attach the Status Tag to my equipment? The tags are designed with multiple fixing options for versatility. They can be secured using cable ties (often the easiest method for ladders and scaffolding), screws, rivets, or strong adhesive tape. The tag is curved and flexible, allowing it to sit flush against tubes, scaffold poles, or flat surfaces.

8. Can I buy refill checklists without buying new tags? Yes. The system is designed to be cost-effective. Once you have the Status Tags installed, you only need to purchase the refill checklist pads. We stock individual books for all equipment types at HSE Store, so you can top up your supplies as needed.

9. What types of equipment can I inspect with Good To Go Safety? The range is extensive and covers most common workplace equipment. We stock checklists for Ladders, Scaffolding, Podium Steps, Forklifts, MEWPs, Pallet Trucks, Racking, Harnesses, Excavators, Telehandlers, and even fleet vehicles. If you have a specific piece of machinery, there is likely a compatible checklist available.

10. Is this system suitable for temporary or hired equipment? Yes, it is ideal for hired equipment. Because the tags can be attached via cable ties, they can be easily removed without damaging the equipment when it is time to return it. It provides hirers and users with peace of mind that the temporary kit has been inspected and is safe for use on your specific site.