Slips, trips and falls (STFs) are the silent saboteurs in the bustling environments of manufacturing, warehousing and distribution. While machinery injuries often make the headlines, on-the-ground incidents like STFs quietly cost businesses dearly in lost time, injuries and hard-earned profits. With plastic strapping from parcels and pallets playing a notorious supporting role, it’s time for industry leaders to address this hidden hazard head-on.

The Scale of the Problem

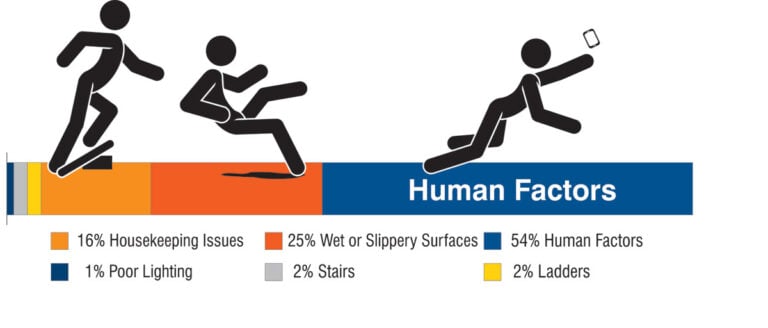

Statistics are eye-opening: in the UK alone, from 2017/18 to 2019/20, nearly 971,000 working days were lost due to slip, trip and fall injuries—averaging 8.5 days lost per case. What’s more, a staggering 32% of major workplace injuries are down to slips and trips, making these the single biggest cause of serious, non-fatal incidents in UK facilities. Warehousing and distribution aren’t spared either; over a quarter (26%) of warehouse staff report being affected by an STF in a given year.

The Cost and Impact on Business

The financial fallout is equally harsh. The direct cost to UK employers exceeds £500million annually, accounting for lost productivity, legal fees, and compensation. But that’s only the tip of the iceberg; hidden costs—like delays in delivery, temporary workforce arrangements, and time spent training new hires—further undermine company performance and morale. When staff are off sick, expertise drains from the floor, delaying schedules and denting customer confidence.

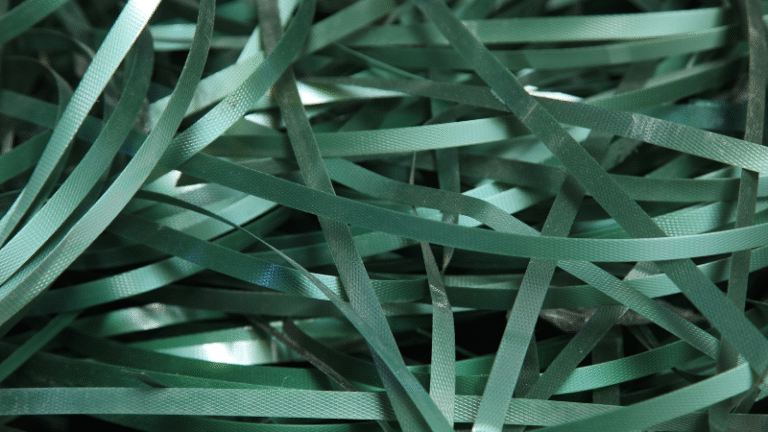

Why Plastic Strapping Is a Major Culprit

In fast-paced environments, plastic strapping from parcels and pallets is everywhere. It’s lightweight, tough, and—when left on the floor—devilishly hard to spot. Many slips are linked to floor contamination, including plastic strapping and similar packaging offcuts. Not only can tangled strapping cause tripping, but over-tensioned or poorly handled straps present cutting and snapping hazards—injuries that cost even more in lost time and repairs.

Key triggers:

Discarded strapping left in walkways or packing areas.

Over-tensioned straps snapping under load and causing injury.

Poor housekeeping and inadequate waste disposal processes.

Lost Time and Downtime

Every slip or trip slows production. The Health & Safety Executive (HSE) notes that the average STF injury leads to three or more days off work, with many causing much longer absence. In manufacturing, where 424 injuries per 100,000 workers annually are reported, these lost days directly disrupt operations—resulting in missed quotas and delayed shipments.

Waste Management: The First Line of Defence

Slips and trips thrive where workplaces aren’t kept tidy. Effective waste management isn’t just a “nice to have”—it’s a frontline defence. Our range of waste management solutions offers simple, robust ways to tackle the root causes of workplace mess. Recycling stations—like the robust steel 3-bin recycling system—enable quick, easy segregation of recyclables, plastics, and general waste, with durable labels that take the guesswork out of sorting.

-

Redditek Heavy Duty Recycling Station – 240 Litre

£510.46 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Redditek Heavy Duty Recycling Station – 160 Litre

£398.46 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

Keeping It Clean—And Safe—with Shadow Boards

It’s impossible to clean up properly if you can’t find the right tools. That’s where our Cleaning Station Shadow Boards come in. Designed specifically for demanding industrial settings, these bold, wipe-clean boards have a printed silhouette for each cleaning tool—so missing kit is instantly obvious, and downtime wasted in search of a broom or mop is slashed. Colour-coding reduces cross-contamination risks, supporting the highest hygiene standards in every shift.

-

Modulean Shadow Board – Cleaning Equipment XL

£224.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

Introducing the Ingenious Racksack

Innovative products like the Racksack have transformed warehouse waste collection. Made in the UK from tough, reusable polyester, the Racksack hangs from racking or fits trolleys, keeping packaging waste—or hazardous strapping—off the floor and out of harm’s way. Available in clear and colour-coded styles with custom labelling, these sacks make it easy for teams to identify and segregate waste streams for efficient recycling. The result? Fewer tripping hazards, quicker clean-ups, and a serious reduction in waste-to-landfill.

-

Racksack Rollcage

From £48.32 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Racksack Clear

From £47.79 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Racksack

From £43.33 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

Flexible, Custom Waste Solutions

Every workplace is different, which is why customisation matters. The Racksack comes in varied sizes (from 50 to 160 litres) and styles—with single or double compartments for different types of waste. Logos and labels ensure everyone knows exactly what goes where, aiding compliance with strict waste segregation laws and sustainability targets.

Sustainability and Simplicity

Beyond preventing incidents, these solutions pay dividends for your green credentials and bottom line. Switch from black bin liners to Racksacks and you could save nearly £200 per year—while reducing plastic waste and supporting environmental breakthroughs in your operations.

Building a Safety-First Culture

None of these strategies works alone. True, lasting change comes from embedding good housekeeping, clear signage and regular waste audits into your culture. Encouraging tidy habits, rewarding attention to detail, and ensuring the right tools are accessible are all vital in driving down STF incidents.

FAQs

1. Why are slips, trips, and falls so common in warehouses and manufacturing?

Slips, trips, and falls are prevalent because of fast-paced operations, clutter, uneven floors, poor lighting, and stray packaging waste like plastic strapping left in walkways.

2. What are the real costs to businesses?

Direct costs hit £500million a year, not counting hidden costs like downtime, lost expertise, and reputation damage from missed orders.

3. How does plastic strapping contribute to incidents?

It’s often left loose or discarded on floors and can cause trips, slips or cuts, especially if it’s clear or hard to spot on certain surfaces.

4. What should we do with used plastic strapping?

Always put it immediately in a dedicated, labelled waste solution like a Racksack or recycling station—don’t let it build up around work areas.

5. How do Cleaning Station Shadow Boards help?

They consolidate cleaning equipment, make missing items obvious, and save time—proactively supporting tidiness and reducing hazards.

6. What makes Racksack unique?

Racksack is reusable, robust, and can be customised with logos and waste stream graphics. Its design keeps waste out of walkways and streamlines recycling.

7. Can waste systems improve productivity?

Yes—fewer tripping hazards mean fewer accidents, less down-time, and smoother operations on the floor.

8. Are there legal requirements around STF prevention?

Absolutely. UK law requires hazards to be assessed and addressed with reasonable controls, including effective housekeeping and waste management.

9. What other risks do plastic strapping pose?

Not just trips—over-tensioned strapping can snap and cause cuts or other injuries if mishandled.

10. How do we get started with better waste management?

Start by auditing your current system, investing in visible, easy-to-use solutions (like those offered by us here at HSE Store) and training teams on correct segregation and regular tidying routines.

A clean, well-organised site isn’t just about compliance—it’s about protecting people, boosting productivity and building a culture that values safety as much as success.