-

Good To Go Safety Status Tag

From £7.50 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

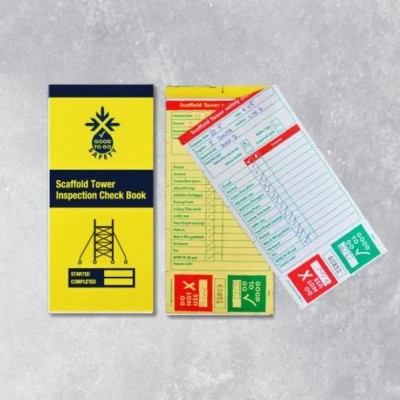

Scaffold Tower Inspection Check Book – 25 Checklists

From £6.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Good To Go – Equipment Inspection Book Dispenser

From £12.50 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Good To Go – Weather Resistant Inspection Holder

From £6.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Good To Go – Equipment Inspection Check Book Wallet & Pen

From £5.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

Scaffold Tower Inspections – Maximise Safety, Ensure Compliance & Protect Your Workforce

Why Scaffold Tower Inspections Are Essential for Your Business

Falls from height remain one of the leading causes of work-related fatalities and injuries in the UK. According to HSE statistics, around 14 people suffered non-fatal falls from height every day in 2019/20, with the real figures likely much higher due to under-reporting. Scaffold towers, while vital for safe access and working at height, pose significant risks if not assembled, maintained, or inspected properly. Common incidents involve falls due to incorrect erection, missing guardrails, or tower overturn during movement, often caused by unsafe work practices or damaged equipment.

Competent assembly by trained personnel is crucial. Approved training schemes help confirm workers’ specialization in safe scaffold tower erection, use, and dismantling. Regular, documented scaffold tower inspections ensure structural integrity, identify defects, and prevent misuse—helping businesses comply with legal frameworks such as the Work at Height Regulations (WAHR), PASMA guidelines, and HSE best practices.

Comprehensive Scaffold Tower Inspection Solutions We Supply

HSE Store supplies a leading range of scaffold tower inspection products from Good to Go Safety to streamline your safety checks and compliance management:

-

Scaffold Tower Inspection Checklists/Check Books: Detailed, easy-to-use pre-use and periodic inspection checklists to identify common risks including missing components, stability issues, guardrails, bracing, and platform safety. Each completed checklist produces a carbonless duplicate for management and audit records.

-

Status Tags: Attach these universal, low-profile tags at scaffold entry points for maximum visibility. They display the current inspection status and date, providing a clear “Good to Go” or “Do Not Use” message—helping to prevent unsafe use and ensure continuous safety awareness on site.

-

Tamper Evident Security Seals: Protect the inspection documentation and tags from unauthorised modifications or removals.

-

Information Posters: Clearly set out scaffold inspection protocols and promote safe working habits and compliance throughout your workforce.

-

Protective Wallets & Storage Boxes: Keep checklists, tags, and accessories clean, secure, and accessible for easy on-site use and record keeping.

These products help implement a robust tiered inspection programme, suitable for daily pre-use checks and formal inspections every seven days or in line with site-specific requirements.

Benefits of Using Scaffold Tower Inspection Products

Implementing a consistent scaffold tower inspection regime delivers these vital business advantages:

-

Prevent Falls and Injuries: Identify missing, faulty or incorrectly installed components such as guardrails or stabilisers before they cause harm.

-

Comply with WAHR, PASMA & HSE Requirements: Maintain legally required records and evidence of competent scaffold management.

-

Reduce Operational Disruptions: Detect faults early and schedule repairs promptly to avoid costly accident investigations or work stoppages.

-

Boost Worker Confidence: A clearly displayed inspection status reassures users the tower is safe to use, reinforcing a strong safety culture.

-

Streamline Audit and Incident Investigation Processes: Duplicate checklist copies provide a reliable chain of inspection records for management and enforcement bodies.

Suitable Industries and Typical Users of Scaffold Tower Inspection Products

Scaffold towers are used widely across industries including:

-

Construction and Civil Engineering

-

Facilities Management and Maintenance

-

Event and Exhibition Setup

-

Warehousing and Logistics

-

Industrial and Commercial Building Services

Key users of scaffold tower inspection systems include:

-

Tower Erectors and Operators: Carry out daily pre-use inspections before access and throughout use.

-

Site Supervisors and Managers: Oversee inspection compliance and co-ordinate corrective actions for identified issues.

-

Health & Safety Advisers: Review inspection records, conduct audits and ensure adherence to legislation.

-

Maintenance & Repair Teams: Use inspection findings to prioritise repairs and replacements.

-

Senior Leadership and Directors: Ensure legal compliance, safe work environments, and organisational safety culture.

How the Good to Go Safety Scaffold Tower Inspection System Works

Our scaffold tower inspection system enables seamless safety management with simple steps:

-

Pre-use inspections are performed using the comprehensive scaffold tower safety checklist.

-

The completed checklist is removed from the book and placed inside a status tag attached at the point of tower entry.

-

The status tag displays the latest inspection date and result — either “Good to Go” or “Do Not Use”, making safety status instantly clear to all site personnel.

-

Duplicate checklist copies are retained in the check book to create a permanent audit trail for management and regulatory compliance.

-

Inspections are performed following erection and then regularly (typically every 7 days for towers used in construction work where falls from 2m+ are possible), or as defined by risk assessments.

-

If any faults or omissions are found during inspection, the tower is immediately quarantined until safe repairs and re-inspection take place.

The compact design of the tag fits flush with scaffold tubes using cable ties, minimising snag hazards and maximising visibility.

Frequently Asked Questions (FAQs)

1. How often should scaffold towers be inspected?

All towers must be inspected after assembly and at suitable intervals—usually every 7 days when used at heights where falls of 2m or more are possible, and prior to first use. Daily pre-use checks by competent persons are also essential.

2. Who can carry out scaffold tower inspections?

Inspections must be completed by competent persons with the appropriate training and experience in scaffold safety, including erection supervisors and qualified inspectors.

3. What happens if a scaffold tower fails inspection?

If faults are found, the tower must be clearly tagged as “Do Not Use” and taken out of service. Only after corrective action and a safe re-inspection should it return to use.

4. Are scaffold tower inspections required by law?

Yes. Scaffold towers are covered under the Work at Height Regulations (WAHR), and inspections must follow PASMA and HSE best practice guidance, including record keeping for enforcement and safety audits.

5. Why use dedicated scaffold tower inspection products and status tags?

Dedicated checklists ensure all critical components and safety aspects are inspected. Status tags provide instant visual communication of tower safety, promote user accountability, and maintain auditable inspection records.

Choose HSE Store’s Scaffold Tower Inspection products for trusted, compliant, and efficient tower safety management—protecting your workforce and business on every project.