-

Good To Go Safety Status Tag

From £7.50 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

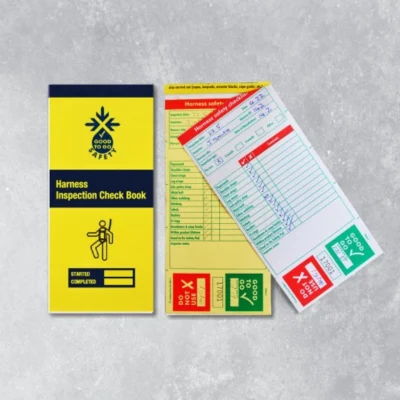

Harness Inspection Check Book – 25 Checklists

From £6.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Good To Go – Equipment Inspection Book Dispenser

From £12.50 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Good To Go – Weather Resistant Inspection Holder

From £6.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Good To Go – Equipment Inspection Check Book Wallet & Pen

From £5.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

Harness Inspections – The Safeguard for Working at Height

Why Harness Inspections Are Critical for Your Business

A harness is a cornerstone of any fall protection programme, providing vital safety for technicians and workers operating at height. However, a harness is only as reliable as the inspection and maintenance regime behind it. Defects and damage can easily go unnoticed, and undetected failures can result in serious injuries or even fatalities. UK regulations—most notably the Work at Height Regulations (WAHR) and the Personal Protective Equipment at Work Regulations—demand that harnesses and associated safety equipment must be inspected and maintained at regular, documented intervals by a competent person. Regular checks not only ensure legal compliance but are a proactive step in safeguarding your workforce, reputation, and bottom line.

Comprehensive Harness Inspection Solutions from HSE Store

At HSE Store, we supply a complete range of harness inspection products designed for simplicity, thoroughness, and full auditability. Our product offering includes:

-

Good to Go Safety Harness Inspection Check Books: These checklists cover all the essential visual and tactile inspections, detailing every part of the harness. Duplicate carbon copies provide clear, immediate audit trails for management and regulators.

-

Status Tags: Clearly attached status tags display a “Do Not Use” message until a checklist has been completed and inserted. These tags provide instant visual confirmation of compliance for every harness ready for use.

-

Tamper Evident Seals: Ensure that inspections cannot be falsified and that every checklist and tag represents a genuine safety check.

-

Information Posters: Prominently placed posters reinforce inspection routines and best practices to everyone working at height.

-

Protective Wallets & Storage Boxes: Store harnesses and inspection records securely, protecting vital documentation from damage or loss.

Every item in our range supports a safety-first culture and helps you meet your legal obligations efficiently.

Harness Inspection Benefits

Implementing structured inspection regimes with purpose-designed products brings substantial benefits:

-

Reduces the Risk of Accidents: Spot faults before they become life-threatening issues, minimising workplace injuries.

-

Demonstrates Compliance: Easily provide evidence to the HSE or insurers when required, thanks to duplicate records and visible status tags.

-

Prevents Costly Downtime: Detect and address minor wear or damage before it leads to expensive repairs or replacements.

-

Boosts Workforce Confidence: Reassure your team that they are working in a safe environment with quality-assured equipment.

-

Strengthens Your Safety Reputation: Upholding best practice demonstrates commitment, building trust among clients and employees.

Suitable Industries and Key Users

Harness inspections are essential across all sectors where work at height is carried out, including:

-

Construction and Civil Engineering

-

Maintenance and Facilities Management

-

Energy and Utilities

-

Rope Access and Industrial Cleaning

-

Warehousing, Events, and Telecoms

Key personnel include:

-

Technicians and Operatives: Responsible for daily pre-use buddy checks.

-

Supervisors and Managers: Oversee inspection regimes, recordkeeping, and remedial actions.

-

Health & Safety Advisors: Develop, audit, and refine inspection practices.

-

Maintenance Teams: Review inspection findings and address wear or defects.

-

Directors and Owners: Fulfil legal duties and reinforce a safety culture.

Inspection Frequency and Process

Inspections generally fall into three categories:

-

Pre-use checks: Carried out by the user before each use, focusing on obvious wear or damage.

-

Detailed (thorough) inspections: Formal inspections performed by a competent person before first use, when receiving from third parties, and every six months—or more frequently if recommended by a risk assessment or manufacturer guidance.

-

Interim inspections: Added between thorough checks when equipment faces high wear, hazardous conditions, or after any incidents.

Frequently Asked Questions (FAQs)

1. How often must harnesses be inspected?

Harnesses should have a pre-use inspection before every use and a detailed inspection every six months, or every three months in high-risk environments. Manufacturer guidance may recommend shorter intervals.

2. Who is qualified to carry out harness inspections?

A competent person with suitable training, experience, and knowledge of harness use. This can include health & safety officers or certified fall protection professionals.

3. What records must be kept?

All completed checklists, dates, inspector names, serial numbers, and action taken for defects. Records should be retained on site and kept for at least three months after use as per WAHR.

4. What should I do if a defect is found during inspection?

Remove the harness from service immediately. Defective items must be repaired (if feasible) or replaced. Clearly tag and report the defect and only return harnesses to service after re-inspection.

5. Why use dedicated inspection products instead of generic forms?

Purpose-built checklists ensure every critical safety aspect is covered, and tagged status eliminates guesswork. They provide visible compliance and immediate proof to both users and inspectors.

Choose HSE Store’s Harness Inspection solutions for robust compliance, enhanced safety, and peace of mind—protecting your business and every worker at height.