-

Good To Go Safety Status Tag

From £7.50 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

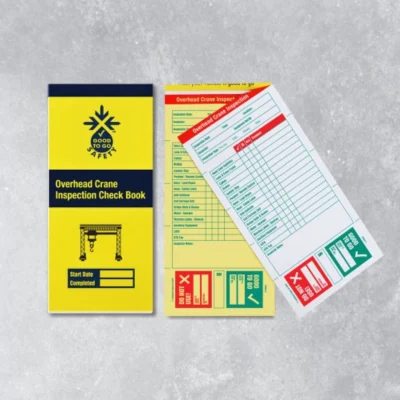

Overhead Crane Check Book – 25 Checklists

From £6.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Good To Go – Equipment Inspection Book Dispenser

From £12.50 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Good To Go – Weather Resistant Inspection Holder

From £6.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Good To Go – Equipment Inspection Check Book Wallet & Pen

From £5.00 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

Overhead Crane Inspections – Ensure Safety, Compliance and Operational Efficiency

Why Overhead Crane Inspections Are Crucial for Your Business

Overhead cranes—including overhead travelling cranes and gantry cranes—are indispensable in many industrial settings, moving heavy loads with precision. However, these powerful machines also present significant risks when not properly maintained and inspected. Crane failures can result in dropped loads, property damage, injury, or even fatalities. With legal requirements mandating comprehensive thorough examinations every 12 months and after substantial changes, regular overhead crane inspections are vital for operational safety and compliance. Proactive inspections help identify faults early, reduce accidents, and protect all personnel and assets on site.

Sadly, statistics show that around 25% of crane incidents involve dropped loads, with approximately 60% of these linked to poor maintenance and 15% to wire rope or cable failure. This highlights the importance of combining scheduled specialist examinations with frequent visual and functional checks throughout the year to ensure cranes remain safe and reliable.

Our Range of Overhead Crane Inspection Products

At HSE Store, we offer a comprehensive range of overhead crane inspection products from Good to Go Safety that simplify the inspection process and provide vital documentation for compliance:

-

Overhead Crane Checklist Books: Pre-formatted inspection checklists designed for daily pre-use, weekly, monthly, or customised inspection intervals in line with manufacturer recommendations and site needs. Each checklist creates a carbonless duplicate for management records and audit trails.

-

Status Tags: Attached securely to the crane control panel, these highly visible tags clearly display if the crane is “Good to Go” or “Do Not Use,” with the inspection date and status for all personnel to see.

-

Tamper Evident Seals: Prevent tampering or unauthorised removal of inspection sheets and tags, maintaining integrity and safety trust.

-

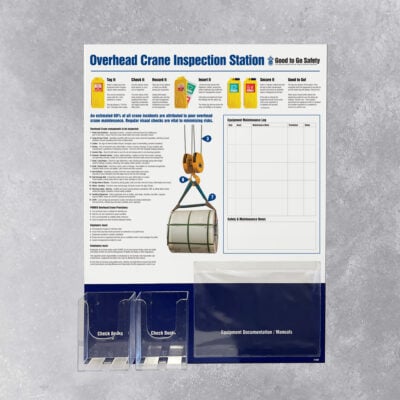

Information Posters: Reinforce inspection protocols, raise safety awareness, and remind operators and site staff about their inspection duties.

-

Protective Wallets and Storage Boxes: Organise inspection documentation, ensuring records are protected and accessible during audits or investigations.

Together, these products establish a strong culture of safety and compliance, enabling ongoing monitoring between thorough specialist examinations.

Who Should Use Overhead Crane Inspection Products?

Overhead crane inspection solutions are essential for many industries that rely on lifting heavy materials, including:

-

Manufacturing and Assembly Plants

-

Warehousing and Distribution Centres

-

Construction Sites and Civil Engineering Projects

-

Steel Fabrication and Metalworking

-

Logistics and Ports

-

Aerospace and Automotive Industries

The key personnel involved include:

-

Crane Operators: Responsible for carrying out daily pre-use checks and alerting management to any immediate concerns.

-

Site Supervisors and Managers: Monitor inspection adherence, review records, and coordinate maintenance actions.

-

Health & Safety Officers: Audit inspection processes and foster compliance.

-

Maintenance Technicians: Use inspection feedback to conduct preventive maintenance and repairs.

-

Business Owners and Safety Directors: Oversee legal compliance, risk management, and operational continuity.

Benefits of Using Overhead Crane Inspection Systems

Implementing a structured overhead crane inspection system using Good to Go Safety products delivers numerous advantages:

-

Improved Safety: Early detection of faults prevents accidents involving heavy loads, protecting personnel and assets.

-

Legal Compliance: Maintain up-to-date documented inspections supporting statutory thorough examinations required under LOLER and lifting equipment regulations.

-

Reduced Downtime: Spotting defects and wear early reduces unexpected failures and costly operational shutdowns.

-

Clear Communication: Visible tags provide real-time inspection status to operators and site staff, avoiding unsafe crane use.

-

Audit-Ready Records: Duplicate checklists create a reliable audit trail essential for enforcement authorities, insurance claims, and internal reviews.

How the Good to Go Safety Overhead Crane Inspection System Works

Good to Go Safety’s flexible inspection system adapts to your site’s schedule, whether you require daily, weekly, monthly or other customised check intervals. The process is simple:

-

Operators complete the inspection checklist according to site protocol.

-

The checklist is removed from the book and inserted into the status tag, typically attached to the crane’s control panel.

-

The tag displays the inspection date and results, signalling “Good to Go” for safe use or “Do Not Use” if a fault is identified.

-

A duplicate checklist is retained in the check book for management records, providing a verified, chronological history of inspections.

-

If faults are found, the crane is promptly quarantined until repairs are completed and a new safe inspection is carried out.

This comprehensive system reduces risk by ensuring ongoing visibility of crane safety status and streamlines recordkeeping for compliance and operational review.

Frequently Asked Questions (FAQs)

1. How often should overhead cranes be inspected?

Daily pre-use visual and functional checks by operators are essential, with additional formal inspections carried out at least monthly or as recommended by the manufacturer. Thorough examinations by specialists must be done every 12 months or after significant alterations.

2. Who is responsible for conducting overhead crane inspections?

Operators perform daily pre-use checks, while supervisors and safety staff oversee compliance and schedule in-depth inspections and maintenance. Specialist engineers conduct the annual thorough examination.

3. What should happen if a fault is discovered during inspection?

If a defect affecting safe operation is identified, the crane must be immediately taken out of service, clearly tagged “Do Not Use,” and reported to management for repair before use resumes.

4. What records need to be kept for compliance purposes?

Records of all inspections and examinations—including dates, findings, and actions taken—must be securely maintained and made available for inspection by enforcing authorities. The Good to Go Safety system provides duplicate checklists to facilitate this.

5. Why choose dedicated overhead crane inspection products over generic tools?

Specialised products ensure all critical inspection points for overhead cranes are covered, provide visible and immediate status updates to all site personnel, and generate reliable, auditable documentation tailored to lifting equipment safety regulations.

Choose HSE Store for your Overhead Crane Inspection products—maximise safety, maintain compliance, and protect your workforce and assets with industry-leading solutions you can trust.