Safety Barriers - What Are They?

A safety barrier is a physical structure or device designed to prevent or minimize the risk of accidents, injuries, or damage in various environments. Safety barriers are commonly used in industrial settings, construction sites, roadways, and other locations where there is a potential hazard.

These barriers can take many forms, including but not limited to:

Guardrails: Used along roads, bridges, and elevated platforms to prevent vehicles or pedestrians from veering off the edge.

Fences: Installed around hazardous areas such as construction sites, machinery, or electrical equipment to restrict access and prevent unauthorized entry.

Crash barriers: Positioned along highways and racetracks to absorb impact energy and redirect vehicles in the event of a collision, reducing the risk of injury to occupants and damage to property.

Safety bollards: Rigid posts or pillars placed in strategic locations to protect buildings, storefronts, and pedestrian areas from vehicle collisions.

Safety nets: Installed in construction sites or industrial facilities to catch falling objects or personnel, preventing injuries and property damage below.

Fall protection systems: Including guardrails, safety harnesses, and lifelines used in construction, maintenance, and other elevated work environments to prevent falls and mitigate the risk of injury.

Containment barriers: Utilized in chemical plants, laboratories, and other facilities to contain spills or leaks and prevent them from spreading to other areas.

In this article we are specifically referencing and discussing those used in industrial settings.

Guard rails such as walkway barriers, crash barriers which we use to protect plant and equipment from manual handling equipment such as forklift trucks and powered pallet trucks, and also safety bollards for extra protection or traffic restrictions.

Where Are Safety Barriers Used?

Safety barriers are used across a range of industries and sectors, as well as various workplaces. They are mainly used in busy industrial facilities where site vehicles are very common, such as:

- Factories

- Warehouses

- Distribution centres

- Airports

- Car parks

Understanding The Health & Safety

Accident Figures

The below is credit to National Forklift Safety Day

Accident figures based on RIDDOR (Reporting of Injuries, Diseases and Dangerous Occurrences Regulations) over the last three years show that 43% of incidents involving a forklift truck were impacts with a third person.

Of these, around 65% were pedestrians engaged in activities unrelated to the immediate truck operation, 20% were co-workers/supervisors and 15% delivery drivers watching or assisting with loading/unloading their vehicle.

The Health and Safety Executive (HSE) stipulates there must be adequate segregation of forklift trucks and pedestrians within the workplace. A risk assessment must be carried out where frequent MHE movements take place to ensure the safety of all personnel within the workplace.

The Role Of Management

Every year the Health and Safety Executive (HSE) investigates serious injuries and fatalities caused by pedestrians being struck by material handling equipment (MHE) such as forklift trucks.

In most cases, the incidents could have been wholly avoidable provided simple and achievable measures had been taken by those in control of work premises. In so far as possible, removing people from areas of the workplace where vehicles operate should be the rule, but where this is not possible measures to avoid collisions should be installed and the ideal way to achieve this is through the installation of physical barriers.

Where barriers are not practical, other means of ensuring safe movement of pedestrians and vehicles must be considered. This includes clear demarcation of traffic routes using paint on the floor, effective signage and other instructions. All measures should be strictly enforced. It is unacceptable to devise systems and then not ensure they are being effective.

Forklifts are the primary causes of incidents and injuries in workplaces and are most dominant in industries such as manufacturing, agriculture, and warehouses.

These forklift accidents often include overturned forklifts and collisions with pedestrians, pallets, or other equipment.

Importantly, these forklift accidents can not only cause costly damage to equipment, but run the risk of causing serious injury and even death to pedestrians in the vicinity. It is therefore essential that forklift operators be trained to operate forklifts safely.

Whilst implementing safe operational procedures to mitigate the risk of incidents and injuries, the use of safety barriers takes safety management to the next level.

Improving Safety

The chief purpose of using safety barriers within the workplace is to reduce, control, and mitigate risk or the potential of incidents or injuries occurring.

Safety barriers are an easy and efficient method to improve safety in warehouse.

When safety barriers are erected, they restrict easy access to areas where forklifts are in operation to reduce the chances of an accident occurring. They offer a clear highly visible perimeter for the operators to ensure that they are unable to drift into marked pedestrian areas.

Implementing A Safety Strategy

Every workplace has a level of risk and for this reason, having safety barriers is important in creating a safer workplace.

We know that risk cannot be eliminated, therefore managers need to constantly assess workplaces and apply the most appropriate safety solutions.

There are a variety of safety barriers, that are built to manage a specific hazard or meet a specific need, depending on the nature of the area that is being secured.

Being aware of compliance with the current standards is important when choosing the right barrier for your environment.

For example, there are specific barriers for heights and elevated operational areas, including mezzanine floors. Some barriers are of a modular design with some fully welded. Others may be designed to provide security when only a short-term temporary solution is required.

Much research has been conducted over the years around the types of safety barriers that are available on the market with new technology emerging to prevent or at least reduce workplace incidents and injuries.

Safety barriers help boost the workers’ physical awareness of their surroundings and even by denying them access to some dangerous areas.

Vehicular Protection

The advantages of implementing safety barriers in the workplace is to prevent damage to the vehicular fleet such as the forklifts, trucks and flatbeds which could result in costly damages. It takes a split second of carelessness from a vehicle operator for an accident to occur and the possibilities are endless.

In an unforeseeable event where a collision may occur, a safety barrier will dramatically lower the risk of physical injury and expansive damage to the vehicle of any object or pedestrian in the immediate proximity of the incident.

It is important to review what types of safety barriers you have, and to make sure you have the most efficient model available as outdated or damaged barriers could cause excessive damage in the event of a forklift accident and have a higher risk of injury to the operators.

Property & Equipment Protection

Safety barriers can prevent serious incidents and injuries by powered industrial trucks e.g. forklifts from getting involved in serious accidents in a workplace environment.

In addition, these safety barriers can also prevent vehicles from damaging the equipment or stock.

Without safety barriers, the stock or equipment, and vehicles may be exposed to accidental damage when a forklift accident occurs. In such a case, this comes at a cost to the business due to repairs to the vehicle or the replacement of the stock or equipment

Employee Awareness

The safety barrier is also designed to provide physical awareness to workers and pedestrians of their surroundings.

Without this awareness accidents are likely to occur, for example, where workers may fail to hear the reversing sound of a forklift or even the sound of the fire alarm.

It is paramount that the workers are constantly alert as to where they are and where danger might be lurking.

The presence of safety barriers helps to maintain that awareness. The fact that safety barriers are in an area is an indication that moving vehicle will be present and worker must be alert and take the necessary precaution when moving within those surroundings. This means they can make sure they are not in the path of any forklifts or loading trucks.

Business Profitability

Clearly, the importance of safety barriers in some workplaces cannot be overstated.

They help prevent workers and even vehicles from incident and accidents and are also effective in keeping stock and equipment safe and free from damage, thus saving the bottom-line.

Why Are Safety Barriers Yellow?

When it comes to safety, the most important factor in a safety implement’s performance is the durability. It doesn’t necessarily have to look attractive so long as it serves a protective purpose. However at HSE Store we like to provide both a protective barrier but also an attractive and standout colour.

Normally we wouldn’t hammer home the importance of how barriers look but we believe the visual benefits are just as life-saving as the physical benefits they provide.

There isn’t really any point in having a safety barrier if it isn’t visible. A well-seen safety barrier can act as a comfort blanket for factory workers, knowing they are in the vicinity of possible hazards, therefore increasing their vigilance when working in that particular area.

It’s not just pedestrian workers that benefit from visible safety barriers, though. Vehicle drivers can use safety barriers as guidelines when controlling and steering their vehicle, combining this helping hand with their standard training to keep their vehicle and themselves safe at all times.

Here at HSE Store, we supply a wide range of barriers to cover almost any need or task required.

We only supply the Loadtek range as they are heavy duty in use for applications, and conform and exceed many regulations.

While we have a range of products on offer to choose from, we can also quote and manufacture to any size or shape requirements providing it is safe to do so.

Corner barriers are very important for workplace safety, particularly in environments like manufacturing plants, warehouses, and distribution centres where heavy machinery, equipment, and materials are commonly manoeuvred.

These barriers are strategically placed at corners to mitigate the risk of collisions between moving objects, such as forklifts, powered pallet trucks, or conveyor systems, and stationary structures like walls, pillars, or racks.

By providing a physical barrier, they create a buffer zone that helps prevent accidents, minimizing the potential for damage to property, injuries to personnel, and disruption to operations.

Not only this, but they also contribute to the overall organization and efficiency of the workplace.

By delineating pathways and defining work zones, they help streamline traffic flow and optimize spatial utilization. This not only reduces congestion and improves accessibility but also facilitates the smooth movement of goods and materials throughout the facility.

-

Loadtek Low Level Corner Barrier – Heavy Duty

£118.21 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Loadtek Fully Welded Corner Mesh Walkway Barrier – 1200mm

£404.92 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Loadtek Fully Welded Corner Walkway Barrier – 1200mm

£278.92 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

We all know that barriers in the workplace such as manufacturing facilities and warehouses are of the utmost important to protect people but also equipment and machinery.

Its especially important that these barriers are constructed from a very strong steel base manufacture in order to protect effectively.

Low level barriers may give rise to people asking “Why low level? What’s the reason for this height?”

Believe it or not but low level barriers are the strongest type available, and its a relatively simple physics reason why.

If we think of the base of the barrier as the fulcrum, and the height of the barrier as the lever length, its easy to then understand that the higher the barrier installed, the easier it is to be damaged, knocked over or simply not effective at all.

This is the exact reason low level barriers are the preferred choice in industries that need to protect equipment from forklift trucks and other heavy manual handling equipment such as powered pallet trucks.

Its also not just this reason of strength but also twinned with being the right height for the first point of contact with forklifts and powered pallet trucks.

At HSE Store we supply some of the strongest industrial barriers on the market constructed from heavy duty steel, while also at a very competitive price.

-

Brandsafe Low Level Bumper Barrier – PAS 13 Certified

From £541.85 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Loadtek Low Level Corner Barrier – Heavy Duty

£118.21 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Loadtek Low Level Straight Barrier – Heavy Duty – 1200mm

£142.88 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Loadtek Low Level Straight Barrier – Heavy Duty – 800mm

£127.48 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

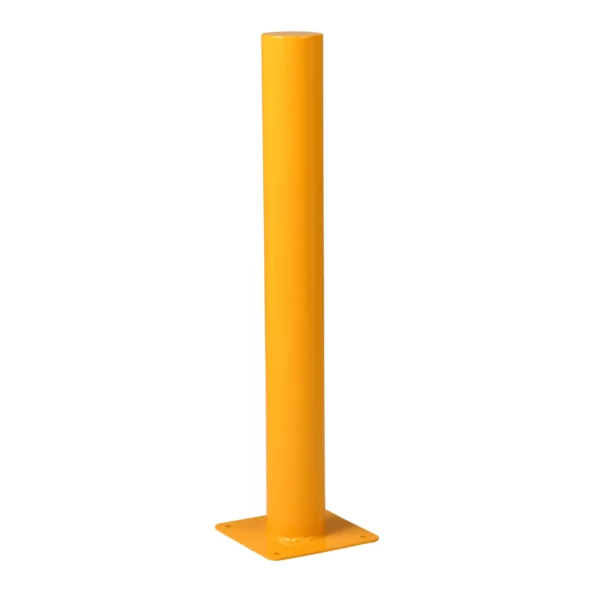

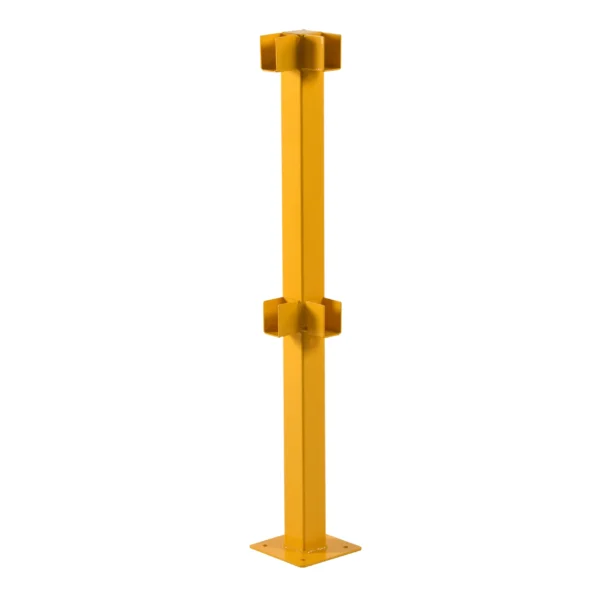

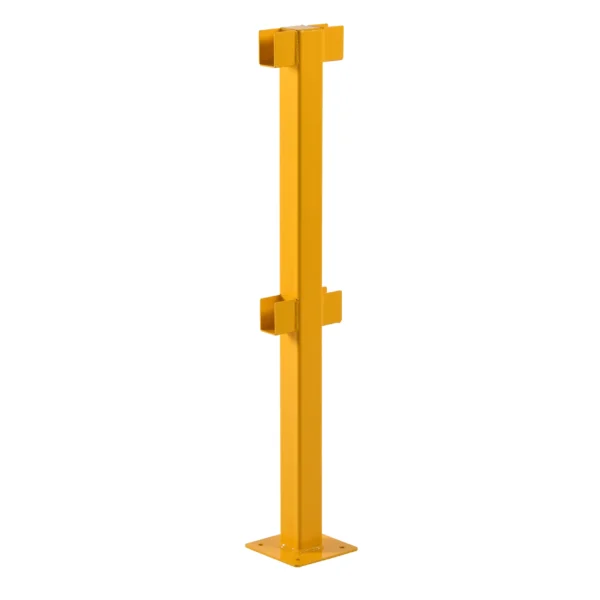

Protective posts and safety bollards serve as stalwart guardians in the workplace, providing robust protection against vehicular impact and safeguarding critical infrastructure, equipment, and personnel.

These sturdy barriers are strategically positioned to shield vulnerable areas such as building corners, doorways, machinery, and pedestrian walkways from accidental collisions caused by vehicles or heavy equipment.

Constructed from durable materials like steel, protective posts and safety bollards possess the strength and resilience necessary to withstand considerable force, effectively absorbing impact energy and minimizing damage.

Their prominent presence acts as a visual deterrent, prompting operators to exercise caution and adhere to designated traffic routes, thereby reducing the likelihood of accidents and enhancing overall workplace safety.

-

Loadtek Protective Steel Traffic Post – Black

From £124.49 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Loadtek Protective Steel Traffic Post – Yellow

From £124.49 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Loadtek Protective Steel Traffic Post – Black & Yellow

From £124.49 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Brandsafe Protection Safety Bollard – PAS 13 Certified

From £295.79 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

Racking protection barriers are critical components in warehouse environments, where storage racks are vulnerable to damage from forklift collisions, pallet impacts, or accidental nudges from manual handling equipment.

These barriers, typically constructed from robust materials like steel, are strategically installed to shield rack uprights, beams, and aisles from potential hazards.

By forming a protective barrier around high-value inventory and structural elements, these barriers minimize the risk of costly damage, ensuring the integrity and stability of the warehouse storage system.

Our strong and resilient racking protection barriers are designed to absorb and redistribute impact forces, effectively dissipating energy to prevent structural deformation or collapse, thereby safeguarding both goods and personnel from harm.

-

Loadtek Low Level Straight Barrier – Heavy Duty 400mm

£109.32 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Loadtek Racking Protection Barrier – U Shape Kit

From £188.61 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Loadtek Protective Steel Traffic Post – Black

From £124.49 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

Straight steel barriers are versatile assets in the workplace, serving multiple functions such as enhancing safety and protecting both employees and equipment assets.

Whether employed as walkway barriers or utilized to prevent equipment damage, these robust barriers provide a sturdy and reliable solution.

When used to delineate walkways or restricted areas, straight steel barriers offer a clear visual demarcation, guiding foot traffic and preventing accidental entry into hazardous zones.

Their durable construction ensures longevity and withstands the rigors of industrial environments, providing a steadfast barrier against unauthorized access or inadvertent intrusion.

Additionally, these barriers can be customized with reflective coatings or bright colours to improve visibility, particularly in low-light conditions, further enhancing their effectiveness in promoting workplace safety.

-

Loadtek Fully Welded Mesh Walkway Barrier – 2400mm

£362.92 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Loadtek Low Level Straight Barrier – Heavy Duty – 1200mm

£142.88 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

Walkway barriers play a pivotal role in workplace safety by delineating pedestrian pathways and separating them from areas where machinery, equipment, or vehicular traffic operate.

These barriers are essential for preventing accidental collisions between pedestrians and moving objects, reducing the risk of serious injuries or fatalities.

By creating clearly defined pedestrian zones, walkway barriers help maintain order and organization in bustling workplaces, promoting smoother traffic flow and minimizing congestion.

Additionally, they serve as visual cues, reminding workers to remain vigilant and adhere to designated walkways, thereby fostering a culture of safety and awareness throughout the workplace.

Constructing walkway barriers from steel offers numerous advantages that contribute to their effectiveness and durability.

Steel is renowned for its strength, resilience, and longevity, making it an ideal material for withstanding the demands of industrial environments.

Unlike other materials, steel barriers can withstand repeated impacts without compromising their structural integrity, ensuring reliable protection for pedestrians over the long term.

-

Loadtek Modular Walkway Barrier – Twin Steel Rails

From £117.17 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page -

Loadtek Fully Welded Mesh Walkway Barrier – 1200mm

£309.07 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

Whether deployed as walkway barriers, machine guards, or perimeter enclosures, our modular barrier systems are characterized by their design, which allows for easy customization and reconfiguration to suit specific requirements.

Unlike traditional barriers, modular systems are composed of interchangeable components that can be assembled, disassembled, or rearranged with minimal effort, facilitating swift modifications to accommodate changes in workflow, layout, or safety protocols.

This versatility makes modular barriers an ideal solution for dynamic industrial environments where operational needs may vary over time.

By incorporating features such as integrated access gates, signage holders, and visibility panels, these barriers can be tailored to address specific safety challenges while maintaining optimal visibility and accessibility

-

Loadtek Modular Walkway Barrier – Twin Steel Rails

From £117.17 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

What To Look For When Buying Safety Barriers

Here at HSE Store we aim to provide only the very best on the market, long term durability and the stand out solution for any application.

Heavy Duty Construction

Our steel barriers from Loadtek are engineered to withstand the rigors of heavy-duty industrial environments, providing robust protection for personnel, equipment, and infrastructure.

Constructed from high-quality steel, these barriers offer unparalleled strength, durability, and reliability, making them ideal for safeguarding against impacts from forklifts, pallet jacks, and other heavy machinery.

Loadtek’s steel barriers are designed with precision and attention to detail, ensuring seamless integration into various workplace settings while adhering to industry standards for safety and performance

Height - Is It Right For You?

Safety barriers in warehouses and production facilities come in various heights to address specific safety concerns and operational requirements.

Lower-height barriers, typically ranging from knee to waist level, are often used to demarcate pedestrian walkways, segregate work areas, or protect sensitive equipment from accidental contact.

These barriers provide a visual barrier without obstructing visibility, allowing for easy monitoring of surroundings and promoting a clear line of sight for personnel and equipment operators.

On the other hand, taller barriers, extending to shoulder or chest height, are commonly employed to shield personnel from larger machinery, moving parts, or falling objects, offering enhanced protection against potential hazards.

By selecting barriers of appropriate height based on the nature of hazards present and the activities conducted within the facility, employers can create a comprehensive safety infrastructure that prioritizes both visibility and protection, ensuring a safe and secure working environment for all.

Colour Coding

Safety barriers are typically painted bright yellow for several reasons, foremost being their high visibility.

Yellow is a colour that stands out against most backgrounds, making it easier for workers and equipment operators to spot barriers from a distance and avoid potential hazards.

This high visibility helps alert individuals to the presence of barriers, delineating restricted areas and promoting adherence to safety protocols.

In addition to yellow, safety barriers in the UK may also be painted in other colors such as red, orange, or white, depending on specific safety regulations, industry standards, or site requirements.

For instance, red barriers may indicate areas with heightened danger or prohibit entry altogether, while orange barriers might be used to highlight temporary hazards or construction zones.

Proven Manufacture

Our barriers from Loadtek stand as industry leaders with over 45 years of proven manufacturing excellence, setting a benchmark for quality, reliability, and innovation in workplace safety solutions.

With a rich history of expertise and experience, Loadtek has continually refined its barrier systems to meet the evolving needs of industrial environments, ensuring optimal performance and durability.

The longevity of Loadtek barriers speaks to their unparalleled craftsmanship and robust construction, built to withstand the rigors of heavy-duty usage in warehouses, production facilities, and distribution centres.

Their commitment to excellence is evident in every aspect of their barrier systems, from the selection of premium-grade materials to the precision engineering and meticulous attention to detail.

British Made

Opting for British-made safety barriers over foreign imports, such as those from China, offers numerous advantages rooted in quality, reliability, and support.

British manufacturers adhere to stringent quality control measures and standards, ensuring that their products meet or exceed regulatory requirements for safety and performance.

By choosing British-made safety barriers, businesses can trust in the superior craftsmanship and durability of locally sourced materials, as well as the expertise of skilled British workers

Material

Steel safety barriers offer unmatched durability, strength, and resilience, making them far superior to other material types for safeguarding industrial environments.

Unlike materials such as plastic, steel is exceptionally robust and resistant to impacts, providing reliable protection against collisions from heavy machinery, forklifts, and other industrial hazards.

Steel barriers are also highly resistant to corrosion, rust, and degradation, ensuring long-term performance even in harsh or corrosive environments.

Note only all these benefits, but steel’s inherent strength allows for the construction of barriers with thinner profiles, maximizing space efficiency without sacrificing safety.

FAQ's

What Colour Are Safety Barriers?

Yellow, in nearly all scenarios. However some workplaces choose other colours depending on hazards that are needed to be marked against.

What Are Safety Barriers For?

A safety barrier is a physical structure or device designed to prevent or minimize the risk of accidents, injuries, or damage in various environments. Safety barriers are commonly used in industrial settings, construction sites, roadways, and other locations where there is a potential hazard.

What Is An Example Of A Safety Barrier?

Walkway Barriers are one example of a safety barrier.

Why Are Steel Barriers Better?

Steel safety barriers offer unmatched durability, strength, and resilience, making them far superior to other material types for safeguarding industrial environments.

Where Are Safety Barriers Used?

- Factories

- Warehouses

- Distribution centres

- Airports

- Car parks

- More

What Types Of Safety Barriers Are There?

- Walkway Barriers

- Modular Barriers

- Straight Barriers

- Mesh Barriers

- Corner Barriers

- Low Level Barriers

- Racking Protection Barriers

What Are Other Names For Safety Barriers?

Industrial Barrier, Barriers, Crash Barrier, Bollard, Post, Crush Barrier, Handrail Barriers, Safety Guard, Guardrail.

Is A Safety Barrier Mandatory?

No, however, a safety barrier should be implemented as a result of a solid risk assessment whereby a hazard cannot be eliminated, then a safety barrier is an excellent method to reduce the hazard as much as possible.

Final Thoughts

We hope that you enjoyed reading our guide, it should be very engaging and something to think about very carefully from a health and safety point of view while at the same time a revenue increasing investment for your business.

We only supply the best top quality safety equipment here at HSE Store that is manufactured right here in Britain.

For further reading, see the rest of our knowledge base articles by clicking here.

You can view the entire range of our safety barriers by clicking below.