What Are Warehouse Trolleys And Trucks?

Industrial trucks, warehouse trolleys, carts, whatever you may call them, are all a form of manual handling in the workplace. Trolleys and trucks quite simply allow movement of goods in a safe and efficient manner.

Warehouse trolleys and trucks come in various designs and styles to suit many different tasks and operations that you will encounter in an industrial setting such as warehouses, medical facilities, workshops, retail outlets, distribution centres and more.

When we look at what safe and efficient means in terms of using manual handling equipment, we define this as a practice where by without this form of manual handling, injuries and hazards are much more likely and also the capacity and speed of the operation would have been lower.

Is A Trolley And Truck The Same Thing?

Yes and no, let me explain.

There is no standard definition of either because the wording to describe the manual handling equipment that is associated with these can be interchangeable. It can also depend on which part of the country you are from.

Some industry professionals will define a trolley as something on 3 or more wheels and a truck as two wheels such as sack trucks. Others define trucks as lifting equipment and trolleys as handling equipment.

Here at HSE Store we have a simple definition that we try to use, and we think it covers the majority of cases (there’s always an exception).

We like to think of trucks as powered or motorised manual handling equipment such as forklift trucks and powered pallet trucks. And for non powered MHE we like to refer to them at trolleys.

Now obvious this is contradictory to two common items you will think of; Sack Trucks & Pallet Trucks. We understand this and the term sack truck is such a nationwide name that wont ever be changed. This is why you can think of trucks and trolleys as the same thing.

Why Should I Invest In A Truck Or Trolley?

Much like all of our manual handling articles, the reasons for investment are similar and require the same thought processes and reasoning.

These points are in no means placed in an order of importance. In terms of importance the first thing we should be thinking about is safety.

Affordable

All trucks and trolleys for the most part are a straight forward design that has been used for many years now in industrial settings. This keeps the cost down compared to manufacturing something bespoke.

Trucks and trolleys you will find on our store and others come in all shapes and sizes, suitable for many tasks. There’s pretty much a guarantee you can buy something off the shelf so to speak.

When we talk about affordable we don’t just mean in basic price point terms, they’re something that is affordable in a value driven approach too.

Cost Effective

When we talk cost effective, there is a very simple question to ask that will make it hit home about why trucks and trolleys are a no brainer cost effective item.

What would it cost to your business if an employee injured themselves from incorrect manual handling, that could have been prevented with a suitable truck or trolley?

The answer is much much more than the cost of buying one of our trolleys.

It is not only the prevention of lost time at work. Trucks and trolleys also eliminate the need for more than one person when handling large and bulky items. Where large and bulky items may have needed two or three people to lift and move to where is needed, a truck can do this with one person. Using the truck as an extension of themselves, it provides easy and simple movement.

All of these points and more provide an increase in revenue for any business, for a small initial outlay upfront. Its a sound investment that is proven across all industries.

Safety

Trucks and trolleys are designed first and foremost for safety. They reduce and even eliminate manual handling injuries that would normally occur without them.

Manual handling injuries are some of the most common that occur in all workplaces, usually due to poor practices such as not having the right equipment available, or lack of training.

This is the number one point to think about, because it affects everything else in business operations when it goes wrong.

Efficiency

Efficiency across different industries is measured in all sorts of ways. One thing everyone can agree on as a measure is labour effectiveness. What this means is the amount of work achieved per person.

Trucks or trolleys by design allow a single person to not only lift and move the amount of work traditionally done by two or three people, but also at a quicker pace. Due to the easy lifting, correct choice of MHE application and wheel types, efficiency is something that goes through the roof.

Space Saving

Depending on the truck or trolley chosen, these can be beneficial for space saving and storage purposes.

For example, our Boxtek Industrial Trolleys are perfect for storing hazardous items safely while stacking in such a way, that without it all items would have taken up much more floor space.

Platform trucks such as our Loadtek Platform Trolleys are ideal for storing themselves easily and discreetly under shelving and other areas.

- in Box TrolleysSku: boxtekplydoorstrolley

Loadtek Boxtek Mesh Distribution Trolley – With Doors – 2 Plywood Shelves – 500kg Load

From £815.03 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page - in LoadtekSku: tc500platformsingle

Loadtek 500 Series Warehouse Platform Trolley Truck – Platform & Single End – 500kg Load

From £260.47 Ex. VAT Select options This product has multiple variants. The options may be chosen on the product page

Statistics Around Manual Handling In The Workplace

Because warehouse trucks and trolleys are a large part of manual handling activities and tasks, we want to give you some idea of the statistics around manual handling in the workplace.

The below is provided with credit to mastermover.com

On Average 477,000 Working Are Suffering From Work Related musculoskeletal disorder (new or long-standing)

Musculoskeletal disorders (MSDs) typically impact the back, shoulders, upper limbs and neck. Injuries can be caused by a range of activities, from lifting to manually manipulating heavy-wheeled loads. MSDs are often caused by repetitive tasks or processes which result in overexertion and fatigue.

HSE, 2022.

7.3 million working days are lost due to work-related musculoskeletal disorders

It’s no surprise that musculoskeletal disorders from manual handling or exerting tasks result in high staff absence and, in turn, lost working days.

The Health and Safety Executive report that MSDs account for 24% of all days lost due to work-related ill health and work-related illness.

Lost working days have obvious impacts on efficiency and output for businesses and so reducing the risk of MSDs and manual handling operations within the workplace should be a priority.

HSE, 2022.

Manual handling accounts for over a third of all workplace injuries

A lot of organisations don’t recognise issues with manual handling processes or tasks until there is an incident or injury.

With the Health and Safety Executive reporting that 1/3 of all workplace injuries are caused by manual handling tasks, the case for assessing and reducing the risk is clear.

Organisations must prioritise assessing their manual handling processes to understand what tasks present a high risk of manual handling accidents or injuries.

HSE, 2021.

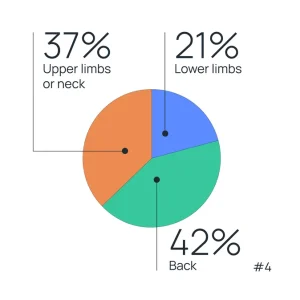

Almost half of MSD conditions affect employees’ backs

Back injuries are often caused by working in awkward positions, repetitive movements or straining and carrying heavy loads.

Likewise, injuries affecting the upper limbs or neck are often a result of lifting, pushing or pulling heavy loads.

HSE, 2022.

Work-related ill health and non-fatal injuries are on the rise

Prior to the coronavirus pandemic, work-related injuries were following a generally flat trend.

However, the current rate of work-related ill health and non-fatal injuries show this is now increasing – surpassing pre-pandemic levels.

IOSH, 2022.

Compensation claims for severe workplace back injuries can be as much as £160k

As we’ve seen from the statistics above, injuries to the back account for 42% of workplace MSDs.

Severe back injuries can be life changing and musculoskeletal disorders affecting the back are often recurring conditions which can significantly impact quality of life.

With this considered, it’s no surprise that severe back injuries can come with heavy compensation pay-outs, as much as £160,000.

UK Law, 2023.

Cost to Britain for workplace injury is around £7.6 billion

HSE reports that workplace injuries cost Britain around £7.6 billion.

The figure includes financial costs covering loss of output, healthcare, and other required payments. It also includes human costs, which are assigned a monetary valuation given to pain/suffering.

HSE, 2020.

Considerations For Buying A Truck Or Trolley For Your Business

One thing we are passionate about here at HSE Store, is giving as much information we can so that you can make the best decision from the start. There is nothing worse than making a purchase and realising what you bought is the wrong model, or the wrong type for the application and task at hand.

Below we will outline all the things you should be considering when looking through our range of trucks and trolleys for your business.

Truck & Trolley Load Capacities

Load capacity is more than likely going to be the most important thing to consider on your purchase journey for a new sack truck.

Firstly you need to consider the tasks that are needed to be performed with the truck, and what the most usual weights are being transported. You may want to cover all the weight of products, or simply narrow it down to an average and the most common weight range.

Remember, while our trucks can probably carry more than the recommended load rating, we wouldn’t advise it for long term durability.

Warehouse Trolley Material

The material of the truck is important to consider especially so with the industry your business operates in.

For example if you operate in the food and drink sector, pharmaceutical drugs, chemicals and likewise, you will more than likely be limited to choosing only stainless steel options due to their high corrosion resistance and hygienic properties. We have stainless trucks available for this.

Aluminium is also an option due to its lightweight nature and strength, it also has a very rust resistant nature when being stored for a long time.

Steel is the most long lasting, and strongest of all the materials you will find on the market. These are by far our most common choice and most supplied. Supplied with a long lasting and durable finish here at HSE Store, coupled with hand made in Britain, you can be sure of the quality and workmanship on offer.

Handle Types

- Loop Handle

These loop handle trucks consist of a single formed tubular handle that wraps around the top of the truck, providing easy one handed use for when speed and efficiency are paramount. Also of course being able to be used by two hands for larger heavier loads. - Twin Handle

Twin handles force the operator to use two hands at all times to keep the load secure and even. These are more of a traditional design and offer greater safety with their usual grip guards or hand grips. - P Handle

These are a design found on sack trucks that allow the sack truck to be loaded much lower to the floor horizontally, and then elevated to position with ease due to its long flowing tubular P shaped ergonomic handles.

Wheel Types

Usually the choice is between Solid Rubber or Pneumatic tyres. Sometimes you will see anti-static wheels, like we have available on our oxygen cylinder trucks.

Solid rubber is the choice for flat fairly even floors in warehouses, factories, offices etc. They offer durability and no punctures, travelling over sharp objects with ease.

Pneumatic tyres have the benefit of a stable load over more uneven ground, while also providing a cushion effect for large unwieldly loads.

Our rough terrain sack trucks come with either option but also have tyre tread patterns in them for anti slip properties and enhanced safety.

Wheel Sizes

Wheel size is an important factor as its usually a clear indicator of load capacity. Generally (but not always) the bigger the tyres, the bigger the load rating.

Bigger wheels are important for uneven flooring, allowing more cushioning or hole resistant travelling.

Shelf or Tray Style

Nearly all of our trucks and trolleys (apart from sack trucks) have shelves and trays that can be customised with different materials and styles.

Some trolleys can be fitted with plastic shelving for both economy or budget constraints, with also the added benefit of ease of cleaning and maintenance.

Plywood shelves are the suitable economy choice for many warehouses and distribution centres due to their low cost and durable finish. They can also be replaced easily when they do gain any damage.

Steel shelves or trays are particularly suited for workshops and engineer stores, they can be cleaned much more easily and are resistant to oils and other fluids usually found in such environments. These steel shelves are usually much stronger and adept at a higher load rating.

Coloured or white finish trays are preferred for retail, commercial and some medical settings (where stainless isn’t required), due to their aesthetic design.

What Type Of Trolleys and Trucks Are Available

Here at HSE Store we aim to provide only the very best on the market, long term durability and the stand out solution for any application.

Below we will show the most comment different types of trucks and trolleys, explain their uses and give an example of what we offer.

Made from strong steel and a long lasting durable hand built attention to detail, our traditional sack truck range are the solution that all industries can take advantage of.

These come in a wide range of load capabilities, here at HSE Store we only supply the best the industry has to offer, all of ours have high capacities of load and will cope almost any task.

We have different tyre options within these such as a pneumatic for uneven surfaces or a need for safer load transport, and also different handle styles to suit.

Platform trucks and trolleys generally dont have any extra shelving in their design. They are particularly used for long and bulky goods, or heavier items.

Seen mostly in workshops and engineer stores for the movement of motors, gearboxes etc. Also incredibly useful for picking tasks in certain warehouses and centres.

Mesh sided trucks allow visibility of products that are stored on these pieces of kit, while also providing stability under transport.

Featuring multiple shelves that can be plywood, steel or plastic, with sometimes adjustable sizing, these are perfect for hazardous goods, or pricier stock items where security is paramount.

Doors can be fitted for extra security, or simply be open fronted for quick loading and unloading.

These types of trucks and trolleys are invaluable in workshops or engineer stores. They can carry all sorts of small parts in an organised fashion, and lots of our trolleys in this category have a recessed deck or tray. The recessed desk proves absolutely valuable when handling small parts, stopping them from dropping and being lost.

Our industrial table trolleys have many options for cupboards built in, or drawer systems for that added storage facility.

Usually all constructed with a solid heavy duty steel frame, these are hard wearing and durable, lasting for many years to come.

Hazardous items have very special requirements for storage. Depending on what you are storing, they have different needs and you should keep up to date with the HSE regulations.

We have available hazardous cages for many applications, such as COSHH trolleys, or gas bottle and cylinder storage cages on trolley wheels.

All regulation signage is provided where applicable, and these items all conform and exceed regulations and expectations.

Service tray trolleys and trucks are usually lower cost and a more standard form factor we think of when we mention trolleys.

These are found in many service environments, such as hospitality, retail, commercial, medical settings and more.

These usually have a more aesthetic design than the more rustic or industrial styles seen in warehouses and the like.

Predominantly made of steel or plastic with a smooth coloured finish, they are easily cleaned, long lasting and durable.

FAQ's

What Can A Trolley Be Used For?

Trolleys can be used for many different tasks and applications. From picking, loading and unloading activities, to storage of hazardous goods or high value items.

What Is An Industrial Trolley?

An industrial trolley or warehouse truck is used for manual handling activities to perform operations in a safe and efficient manner.

How Do You Use A Trolley?

To use a trolley, no matter its style it should be pushed using the appropriate handles while keeping a clear view ahead for any obstacles.

Never over load the trolley in terms of size of item, or weight of product. Refer to the manufacturer instructions and load capacity.

Is Using A Trolley Manual Handling?

Yes, absolutely trucks are considered manual handling equipment. They allow the operator to move larger and heavier loads safely than they would otherwise be capable of.

What Is Another Name For A Trolley?

- Trolley

- Truck

- Industrial Trolley

- Warehouse Truck

- Hand Cart

- Mobile Truck

- Mobile Trolley

What Is The Most Common Injury From Manual Handling?

Back, neck, and shoulder injuries are the most common. Your back is your weakest body part in relation to manual handling. Although back injuries can appear as not too serious initially, they can eventually become serious long-term health problems.

Source: National Accident Helpline

Where Can I Buy An Industrial Trolley?

Right here at HSE Store!

We stock a very wide range of trucks and trolleys suitable for almost any need you can imagine. All of ours are hand made in Britain and built to last.

What Is A Trolley or Truck Made Of?

Usually steel, aluminium or stainless steel.

Each has its own specific use, and detailed above in this article you should decide which is best for you based on your industry and application or task at hand.

Final Thoughts

We hope that you enjoyed reading our guide, while it may not be the most interesting of topics, it should be very engaging and something to think about very carefully from a health and safety point of view while at the same time a revenue increasing investment for your business.

We only supply the best top quality safety equipment here at HSE Store that is manufactured right here in Britain.

For further reading, see the rest of our knowledge base articles by clicking here.

You can view the entire range of our trucks by clicking below.

No products in the cart.

No products in the cart.