What must we do?

Firstly before we establish what we must do with regards to ladders, we must understand what roles there are within the workplace or business we operate in that had ladders available.

If you operate ladders or stepladders as part of your working day, no matter whether frequently or infrequently, its your legal duty to ensure that they are suitable and safe for work and must conduct inspections in accordance with HSE guidelines.

We shouldn’t need to remind ourselves that if an accident occurs due to operation of a faulty ladder, it can result in not only significant fines, but more importantly serious life changing injuries or even fatalities.

If you oversee those who work with ladders for any part of their duties, you must ensure that ladder inspections are carried out correctly and regularly. This will protect not only your organisation and finances, but most importantly the people who work for you.

Why do we need to inspect ladders?

Ladder inspections are absolutely critical when we think about the accident rate and fatality rate in the UK when working at height, its how we mitigate these risks.

If you need to read more about this, you can see our other article on Ladder Safety – Statistics and the Law

How often should ladders be inspected or checked?

Lets start with what HSE says we should do. HSE provides us with guidance for pre use checks, these should be done every time a ladder will be used. Visual inspections should also be conducted as often as required when we take into account the use and risk involved.

We would recommend that a good guideline to follow for formal inspections, would be every month if the ladders are used as part of daily tasks. If the ladders are used on a weekly basis but not daily, then every 3 months, or quarterly would be a good guideline to follow, while for any infrequent use, a 6 month check can be adequate.

How to perform a ladder inspection...

Firstly before ladder inspections are performed, we must have a competent person who can do this. It should be somebody who has been through ladder safety training as part of your company training matrix.

A competent person is defined as someone who has been through the necessary training, has the necessary technical expertise and also any relevant experience.

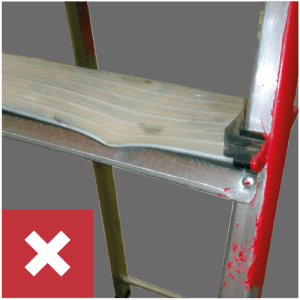

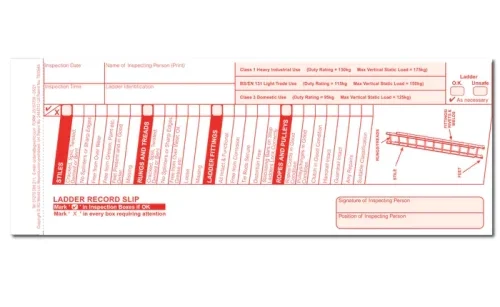

Ladders must be both visually and physically inspected, and records kept of doing so. If any ladders have a fault or issues it must be marked as out of use, with clear markings so your staff know it must not be used. You can also move the affected ladder to a different place, and lock it away to further protect any unauthorized use.

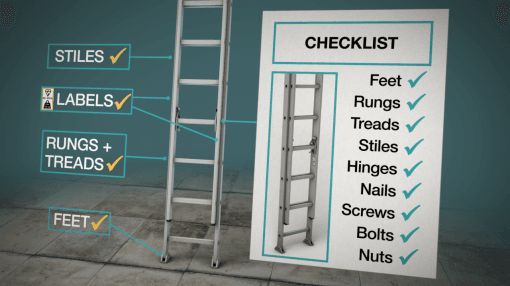

The parts of ladders that we can check would include any or all of the following, depending on the type of ladders:

Feet & Caps

- Feet & top tips fitted, all present,secure, and correct

- Stile ends are undamaged

- All rivets and other fixings are present & secure

- No cracks, cuts, or holes

- Anti-slip surfaces are undamaged

Braces

- No excessive bending, bowing, or folding

- All rivets / other fixings are present and secure

- No cracks, cuts or holes in the cross tubes

- No denting that might compromise its strength

- No corrosion that might compromise its strength

- No rotation, wobbling, or twisting

Fixings

- No severe corrosion or wear – screws, bolts, and rivets are tight and in place

- No holes where fixings may have been but removed

- No signs of wear or damage

Platforms

- No bending or twisting of upper surface

- No cracks, cuts or holes

- No significant denting that might compromise its strength

- Support bar and other attachments are secure and undamaged

- Linkage mechanism is present and opens/closes with no excessive play

- Anti-slip surface is undamaged and clean from contaminants

Rungs / Treads

- No swaging splits with all rungs present and secure

- No bends, bows or twists – creases, cracks, cuts or holes

- No significant denting that might compromise its strength

- Anti-slip surface is undamaged and clean from contaminants

- All rivets / other fixings are present and secure

Labels

- The labels must be securely attached

- They must be legible to the layman

Stiles / Frame Sections

- No bending, twisting, to stiles and frame section

- Hinging of the front to rear frame attachment is secure

- No creases, cracks, cuts or holes

- No significant denting that might compromise its strength

- No contaminants or dirt on stiles

- No significant corrosion on the components

- All end tips are correctly present and secure

- Stops, bushes, and restraint devices are present and undamaged

- Stabilisers are fitted where required – secure and undamaged

Locking catches

- All fixings are tightly in place. are tight and that there is

- No distortion of the stiles where the locking catches are attached

- No bending, twisting or corrosion present

- Locking catches lock and unlock correctly

Rung Hooks

- Rung hooks are all present and secure

- No displacement or looseness

- No signs of bending, cracks, cuts, or holes

- All rivets / other fixings are present and secure

- No significant corrosion of ferrous components

- The hooks fit easily on the rung

Restraint Devices

- No excessive bending, bowing, or folding

- No excessive force required to open/close restraint devices

- All rivets / other fixings are present and secure

- No cracks, cuts, holes or fraying

Guide Brackets

- Guide brackets are all present and secure.

- No displacement or looseness

- No bending, cracks, cuts or holes

- All rivets / other fixings are present and secure

- No significant corrosion of ferrous components

Recap FAQ's

What is a ladder inspection?

A ladder inspection is something we must do as part of our duty to our staff, to protect them and us from harm. It involves visually and physically checking all parts for signs of defects.

How often should I perform a ladder inspection?

That is something that is decided by the company, HSE competent person or staff. It should be based on the ladder usage and risk involved, but must be regularly.

Why do we need to inspect ladders?

We must inspect ladders to keep our staff and us as safe as possible and reduce the risk of harm or serious injury. It is a non-negotiable task.

Who should check ladders in a workplace?

The person who will use the ladders must conduct the checks. This includes pre use checks and also regular formal checks. The business owner or management should ensure the checks are being conducted.

Does a ladder inspection have to be recorded?

Absolutely. If you have any injuries, then HSE may well ask to see your ladder inspection schedule and what was done to prevent the injury happening in the first place. Any ladders not fit for use must be documented also and when they were put back into service.

Further Reading

No products in the cart.

No products in the cart.